Overview

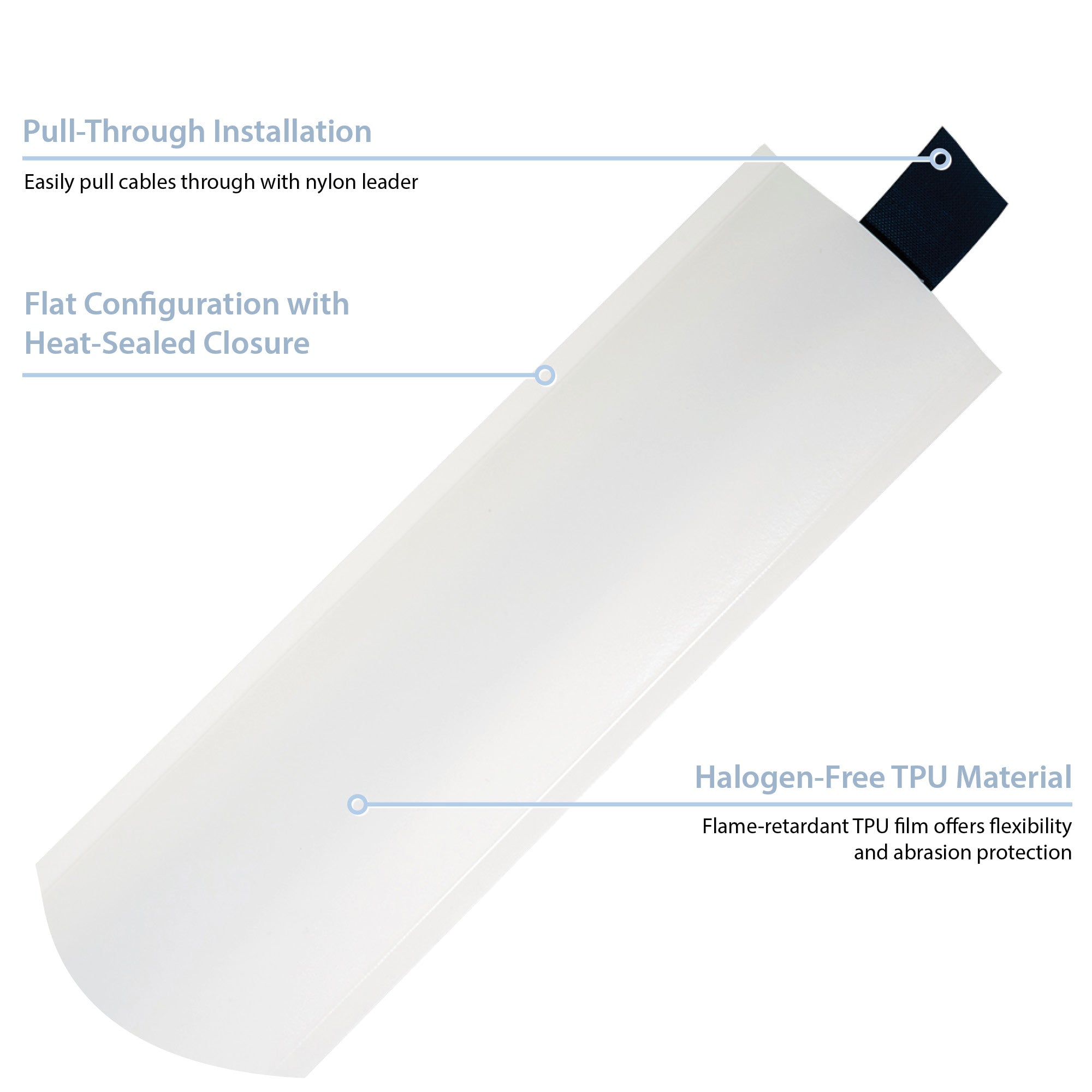

- Nylon cloth leader provides easier installation of pulling wires through

- Lightweight jacketing with the best abrasion resistance

- Operational temperature range is 67°F to 225°F (-55°C to 107°C)

- No tools are required for installation

- Double heat-sealed edges offers complete protection

- Complete, 360-degree protection and bundling

- abrasion-resistant, ozone-resistant, microorganism-resistant jacketing

- UL-rated for flammability, meeting UL 94 V-0

Z flex® (TPU) features the thermoplastic polyurethane film and a nylon cloth leader. The TPU jacketing is halogen free, making this material a viable option for medical industry applications. The jacketing is UL-rated with meeting UL 94 V-0 for flame retardancy. Additionally, the TPU offers superior abrasion resistance, as well as being resistant to ozone damage (Stage 0, “Crack Free”) and microorganisms. The nylon cloth leader allows for an easier installation; just wrap the oxford leader around wires or cables and pull-through. The double heat-sealed edges provide complete protection of components inside from debris, fluids, and other harsh environmental conditions.

Z flex® (TPU) is supplied in spool form, and can be cut to any length needed. Z flex® (TPU) is offered for diameters ranging from 1.625” to 3.5”, with custom sizes available upon request. The operational temperature range is 67°F to 225°F (-55°C to 107°C).

Specifications

Overall Performance

- Material:

- Diameter:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

TPU-20

- Durability:

- REACH:

- Elongation:

- Flammability:

- Color:

- Thickness:

- Thickness Variance:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tensile Strength:

- Ozone Resistance:

Similar products

|

|

|

|

| NAME | Z FLEX® (PFR) POLYURETHANE PULL-THROUGH CABLE BUNDLING | CHANNEL-WRAP® (PFR) ROBOTIC CABLE SLEEVING | Z FLEX® (63) PVC PULL-THROUGH CABLE BUNDLING |

| DESCRIPTION | A military-grade, flame-retardant, pull-through cable and wire protection solution that has a nylon cloth leader. | A flexible, wrap-around robotic cable management sleeve with a Velcro-style hook-and-loop closure for bundling and protecting crucial wires and cables. | A pull-through bundling sleeve equipped with a nylon cloth leader, made of a 0.02” thick military-grade material that offers protection from abrasion & fluid. |

| Closure | Hook-and-Loop (Nylon) | ||

| RoHS | RoHS-6 | RoHS-10 | RoHS-6 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Pull Through | Wrap-Around | Pull Through |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Extreme | Extreme | Low |

| Minimum Operating Temperature | -67°F | -67°F | -4°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 224°F | 199°F | 221°F |

| Flexibility | Best | Best | Better |

| View | View | View |

Z flex® (TPU) Polyurethane Pull-through Cable Bundling

A flame-retardant, pull-through cable protection solution that offers the best in abrasion resistance and is equipped with a nylon cloth leader.

Drawing Number(s): ZT17-10-001

Selected Part Number: ZT17-10-001-1.625-W-W

Features

Benefits

Z flex® (TPU) Polyurethane Pull-through Cable Bundling

Z flex® (TPU) Polyurethane Pull-through Cable Bundling

MATERIAL SPECIFICATIONS