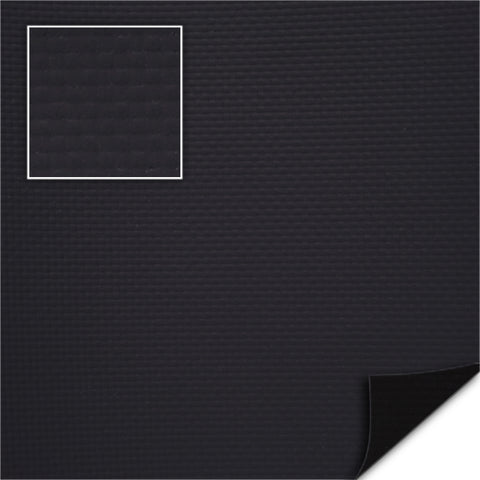

MLB PVC-Coated PET Material

A lightweight, abrasion-resistant, fire-retardant PVC-coated PET material ideal for rugged conditions.

Overview

- UL-rated meeting UL94 VTM-0

- Lightweight at only 0.014" thick

- Coated with fire-retardant PVC

The MLB jacketing is a PVC-coated PET material that is abrasion resistant and fire retardant. The lightweight jacketing is perfect for cable bundling and applications that need lasting protection from rugged conditions. The MTB material is 0.014” thick, and has an operational temperature range of 5°F to 140°F (-15°C to 60°C).

Specifications

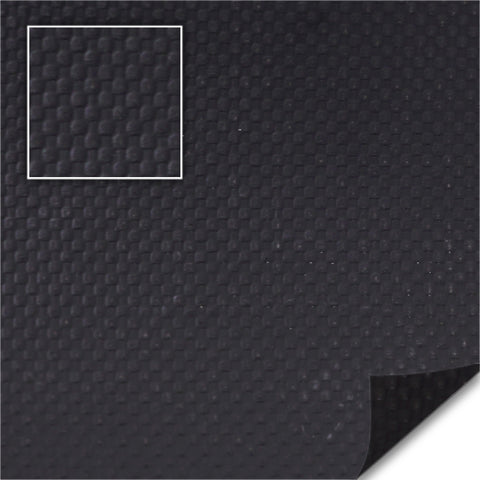

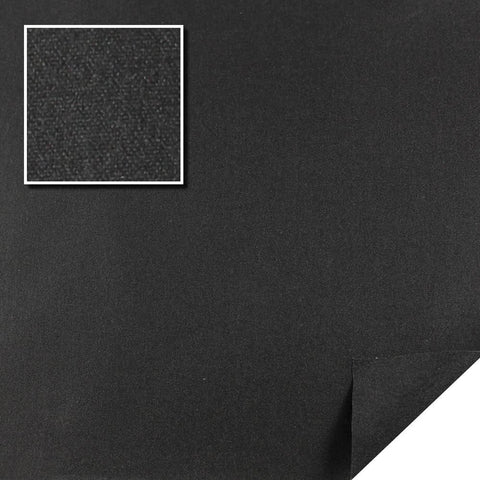

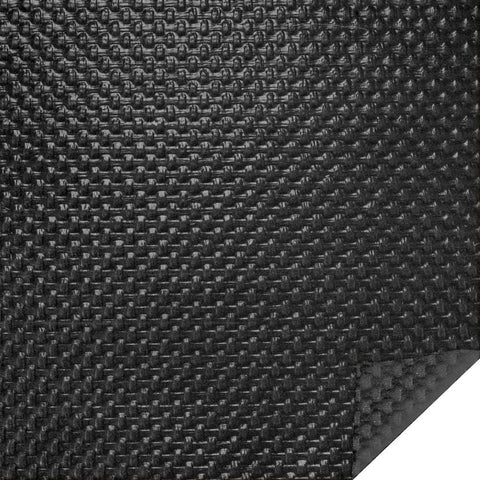

Similar Materials

|

|

|

|

| NAME | RPA-14 - POLYURETHANE COATED ARAMID FABRIC - 14 MIL | RPH-14 - POLYURETHANE COATED POLYESTER FABRIC - 14 MIL | FRC-15 CANVAS FABRIC - 15 MIL |

| DESCRIPTION | A Strong, Medium-Weight, Polyurethane Coated Aramid Fabric | A Flexible, Medium Weight, Polyurethane Coated Polyester Fabric, 14 mil | Lightweight Multi-Purpose Canvas Jacket, 15 Mil |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | Best | |

| Min Temperature | Low | Extreme | Moderate |

| Minimum Operating Temperature | -4°F | -67°F | -22°F |

| Max Temperature | Moderate | Moderate | Low |

| Maximum Operating Temperature | 302°F | 356°F | 140°F |

| Flexibility | Better | Better | |

| View | View | View |

MLB PVC-Coated PET Material

A lightweight, abrasion-resistant, fire-retardant PVC-coated PET material ideal for rugged conditions.

Material Sprcification: 1129

- UL-rated meeting UL94 VTM-0

- Lightweight at only 0.014" thick

- Coated with fire-retardant PVC

SPECIFICATIONS

DESCRIPTION

The MLB jacketing is a PVC-coated PET material that is abrasion resistant and fire retardant. The lightweight jacketing is perfect for cable bundling and applications that need lasting protection from rugged conditions. The MTB material is 0.014” thick, and has an operational temperature range of 5°F to 140°F (-15°C to 60°C).