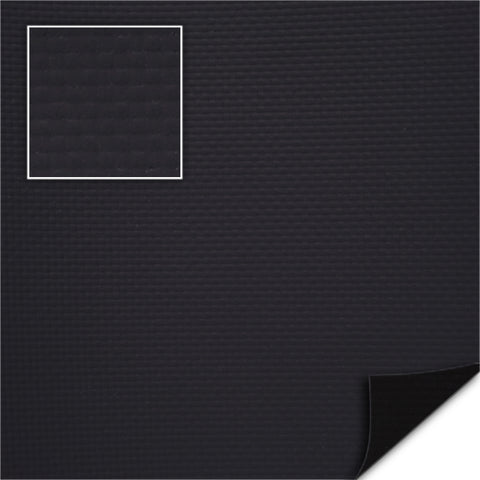

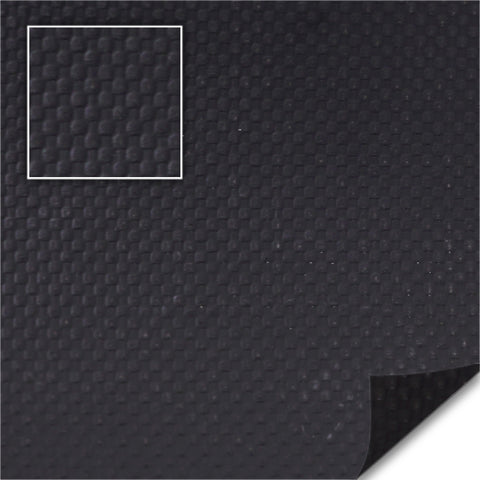

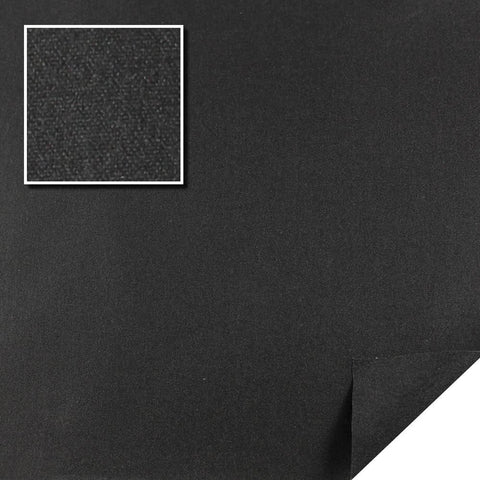

PVC-coated PET Material

A lightweight, abrasion-resistant polyester fabric that is coated with a fire-retardant PVC.

Overview

- UL-rated for flammability meeting UL94 VTM-0

- Abrasion resistant yet lightweight jacketing

- Available in gray, black, and other colors may also be available

PVC-coated PET is a 0.014” thick, lightweight general-purpose jacketing. The material meets UL94 VTM-0 for flammability. There are six colors available, making this material ideal for applications that require color-coding. This jacketing is versatile and can be paired with snap buttons, pressure tracks, zippers, or an adhesive closure. The operational temperature range is -40°F to 179°F (-40°C to 82°C).

Specifications

Similar Materials

|

|

|

|

| NAME | RPA-14 - POLYURETHANE COATED ARAMID FABRIC - 14 MIL | RPH-14 - POLYURETHANE COATED POLYESTER FABRIC - 14 MIL | FRC-15 CANVAS FABRIC - 15 MIL |

| DESCRIPTION | A Strong, Medium-Weight, Polyurethane Coated Aramid Fabric | A Flexible, Medium Weight, Polyurethane Coated Polyester Fabric, 14 mil | Lightweight Multi-Purpose Canvas Jacket, 15 Mil |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | Best | |

| Min Temperature | Low | Extreme | Moderate |

| Minimum Operating Temperature | -4°F | -67°F | -22°F |

| Max Temperature | Moderate | Moderate | Low |

| Maximum Operating Temperature | 302°F | 356°F | 140°F |

| Flexibility | Better | Better | |

| View | View | View |

PVC-coated PET Material

A lightweight, abrasion-resistant polyester fabric that is coated with a fire-retardant PVC.

Material Sprcification: 1117

- UL-rated for flammability meeting UL94 VTM-0

- Abrasion resistant yet lightweight jacketing

- Available in gray, black, and other colors may also be available

SPECIFICATIONS

DESCRIPTION

PVC-coated PET is a 0.014” thick, lightweight general-purpose jacketing. The material meets UL94 VTM-0 for flammability. There are six colors available, making this material ideal for applications that require color-coding. This jacketing is versatile and can be paired with snap buttons, pressure tracks, zippers, or an adhesive closure. The operational temperature range is -40°F to 179°F (-40°C to 82°C).