Overview

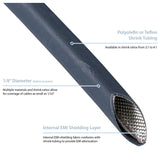

- 2:1, 3:1 or 4:1 shrink ratio

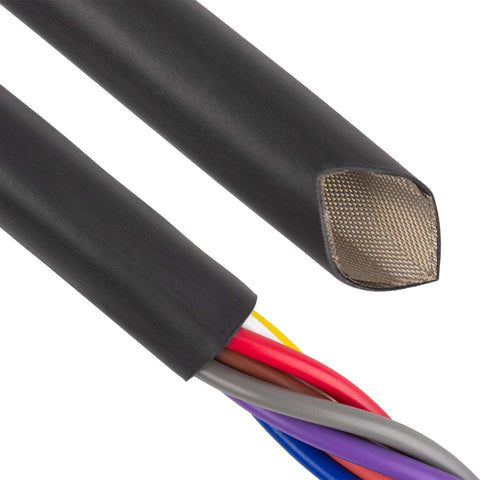

- EMI shielding cloth options provide exceptional shielding properties

- Polyolefin operational temperature range of -67°F to 275°F (-55°C to 135°C), and PTFE material range of -85°F to 500°F* (-65°C to 260°C)

- EMI shielding for the thinnest of wires

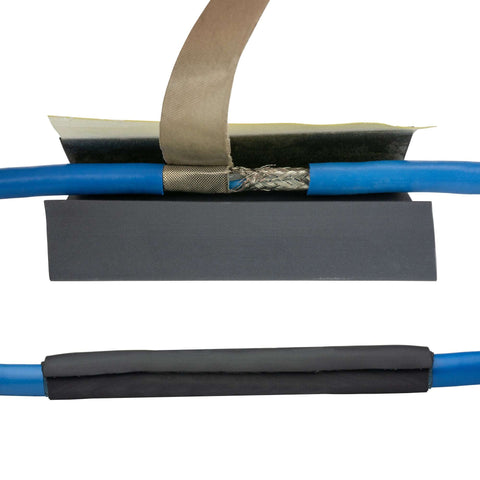

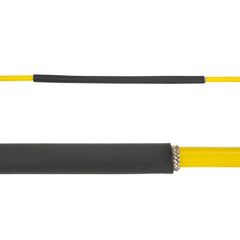

- Easy installation with only requiring a standard heat gun

- Both exterior materials are RoHS compliant and offer lasting durability

- EMI shielding heat-shrink tubing for wires with diameters as small as 0.031”

- These products have an option for either our 3250 or 7200 EMI shielding cloth

- Provides an easy-to-install 360° EMI and abrasion protection solution

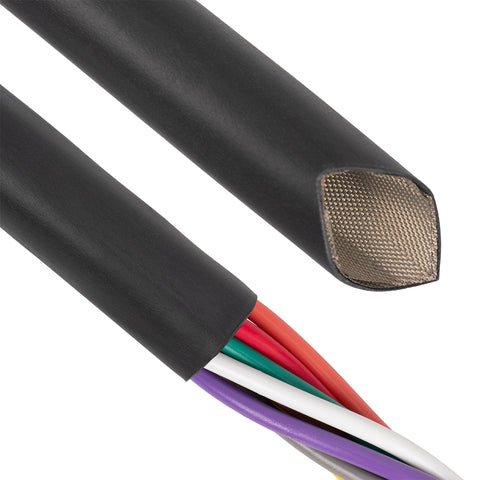

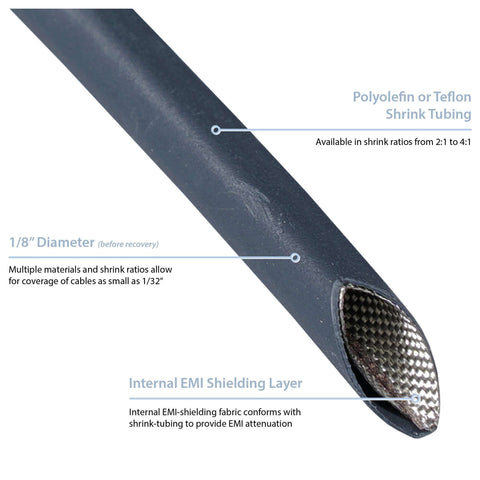

Shrink-N-Shield® (Nano) is an EMI shielding heat shrink for the smallest of wires. Shrink-N-Shield® (Nano) is available in either a polyolefin material for wire diameters as small as 0.0416” in the 3:1 shrink ratio, and 0.0625” in the 2:1 shrink ratio, or in a high-temperature PTFE material for wire diameters as small as 0.031” in the 4:1 shrink ratio.

The Shrink-N-Shield® (Nano) 3:1 or 2:1 is offered in the polyolefin material. The cross-linked polyolefin material is flame-retardant, water-resistant, and flexible, making this jacketing ideal for applications that may experience exposure to flames or fluids. The polyolefin material is also military-grade and meets the military specification for MIL-DTL-23053/5C.

The Shrink-N-Shield® (Nano) 4:1 is offered in the PTFE material. The PTFE Teflon plastic material is flame-retardant, chemically inert, abrasion-resistant, and has low outgassing, making this jacketing desirable for applications requiring a low profile and high flexibility. This heat-shrinkable electrical insulation tubing conforms to the requirements of SAE-AMS-DTL-23053/12 Class 5. The PTFE material is available in clear, allowing complete visibility of the EMI shielding once installed and in the color black.

Shrink-N-Shield® (Nano) also has two different options for EMI shielding fabrics—the Z-3250 and the Z-7200. The 3250 EMI shielding cloth is .004” thick and is made of woven nickel over a copper-plated polyester taffeta material. This cloth is the choice for applications needing extreme flexibility and resistance to environmental degradation. The 7200 EMI shielding cloth is .005” thick and is a woven, copper-plated nylon rip-stop material that is also flexible as well as non-magnetic, halogen-free, and hypoallergenic. This cloth is ideal for applications that cannot use certain magnetic or metal materials. Either shielding cloth will provide exceptional protection from EMI. Additionally, both shielding fabrics are RoHS compliant and offer strong durability for rugged environments.

Shrink-N-Shield® (Nano) is the first Zippertubing® product to offer protection and EMI shielding for extremely small wire diameters. The Shrink-N-Shield® (Nano) in the polyolefin material has an operational temperature range of -67°F to 275°F (-55°C to 135°C), while the PTFE material has a range of -85°F to 500°F* (-65°C to 260°C).

*PTFE can withstand temperatures up to 500°F and maintain shielding effectiveness in a static condition. If the component flexes or moves, shielding performance may be compromised. Shrink-N-Shield® (Nano) PTFE has an operational temperature of up to 302°F that will maintain the effectiveness of the shielding for applications that flex or move.

Class III polyolefin heat-shrink tubing is available upon request.

Specifications

Overall Performance

- Diameter - Before Shrink:

- Material:

- Flammability:

- Heat Shrink Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

- Shrink Ratio:

Polyolefin

- Mil-Spec:

- REACH:

- Dielectric Strength:

- Elongation:

- Flammability:

- Fungicide:

- Longitudinal Shrinkage:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

- Specific Gravity:

- Outgasssing (%TML):

- Outgassing (%CVCM):

- Outgassing (%WVR):

PTFE

- Elongation:

- Flammability:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Shelf Life:

- Shrink Ratio:

Z-3250

Z-7200

Similar products

|

|

|

|

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | PRT® (1553-135) WATER-BLOCKING WRAP-AROUND HEAT SHRINK | SHRINK-N-SHIELD® (3:1) EMI SHIELDED HEAT SHRINK TUBING |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A wrap-around, MIL-SPEC heat shrink paired with a high-temperature, water-blocking adhesive that comes equipped with the Z-3250-Tape™ for shielding against EMI. | A heat-shrink tubing that provides exceptional shielding from EMI, RFI and EMF. |

| Closure | Tape (Specialty Surface) | ||

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Pull-Through | Wrap-Around | Pull-Through |

| Purpose | EMI Shielding | Water Blocking | Small Diameters |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -40°F | -67°F | -67°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 275°F | 275°F | 275°F |

| Flexibility | |||

| View | View | View |

Guides

Shrink-N-Shield® (Nano) EMI Shielded Heat Shrink Tubing

A 1/8" (0.125") diameter (before shrink) EMI shielding heat shrink that is engineered for wires as small as 0.031" in diameter.

Drawing Number(s): ZT99-18-006, ZT15-18-001

Selected Part Number: ZT99-18-006-0.125-B-X24.0

Features

Benefits

Shrink-N-Shield® (Nano) EMI Shielded Heat Shrink Tubing

SHIELDING EFFECTIVENESS - Z-3250, Z-7200

Shrink-N-Shield® (Nano) EMI Shielded Heat Shrink Tubing

MATERIAL SPECIFICATIONS