Overview

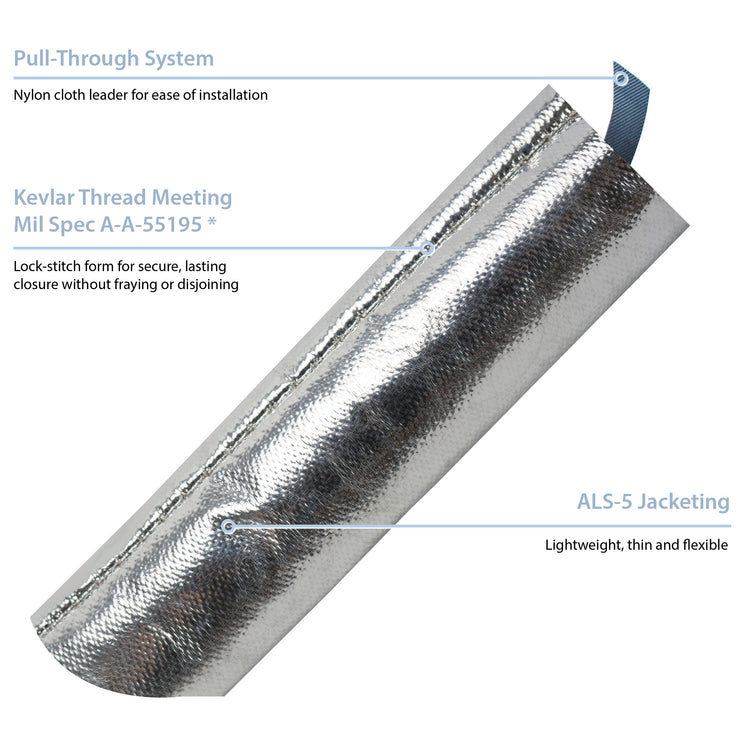

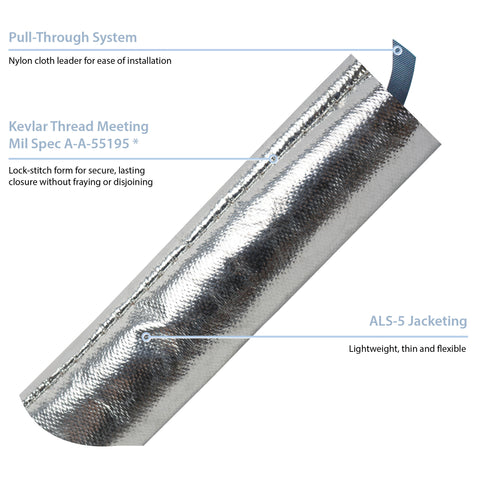

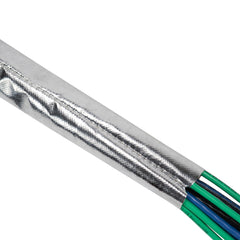

- Pull-through sleeve offers 360-degree protection

- Lightweight material at only 0.006” thick

- Lock-stitched form ensures a secure, lasting closure

ZTT® (ALS-5) is a pull-through heat shielding solution that protects components from moderately high temperatures. The ALS-5 jacketing is a woven fiberglass fabric that has an aluminum surface on one side. The material can handle continuous temperatures of up to 350°F, with radiant temperatures of up to 572°F. This heat reflective jacketing is lightweight at only 0.006” thick and ideal for applications that experience high flexing.

ZTT® (ALS-5) utilizes a strong Kevlar thread is military grade and meets A-A-55195, Type I (formerly MIL-T-44100) specifications. The thread is sewn in a lock-stitch form to ensure no fraying and provides a resilient, lasting closure. The Kevlar thread is extremely durable with having resistance to bacteria, mildew, abrasion, and aging. The solution is inversely sewn into a teardrop shape to provide a clean appearance and reduce abrasion damage during installation. ZTT® (ALS-5) can also be sewn in a traditional teardrop style upon request.

ZTT® is offered in diameters ranging from 0.5” to 3”, with custom shapes and sizes available upon request. The operational temperature range is -40°F to 350°F (-40°C to 177°C).

- Inverse teardrop solution to provide clean appearance and reduce abrasion damage during installation

- Kevlar thread sewn in lock-stitch form to ensure no fraying or disjoining of seam

- Operational temperature range is -40°F to 350°F (-40°C to 177°C)

- Lightweight jacketing can move and bend easily for high flexing applications

- Provides 360-dgree protection of components

- No tools are required for installation; just simply pull wire or cable through

Specifications

Overall Performance

- Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Shelf-Life:

ALS-5

- Weight:

- Break Strength:

- Thickness:

- Radiant Reflectivity:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Shelf Life:

- Tear Strength:

- Emissivity:

Kevlar Thread

Similar products

|

|

|

|

| NAME | ZTT® (ALR-550) HIGH TEMP PULL-THROUGH CABLE SLEEVE | ZIPPER-MESH (ALHTG-65) EMI & HEAT SHIELDED JACKETING | SNAP-GRIP® (SAM-1000) HEAT SHIELDED CABLE BUNDLING |

| DESCRIPTION | A pull-through, flexible heat shielding sleeve that protects components from continuous temperatures as high as 1,022°F. | An all-in-one, wrap-around solution combining the heat shielding of the ALHTG-65 with the EMI shielding of the knitted SHX-4 mesh and a brass zipper. | A heat shielding solution featuring a silicone, polymer-coated fiberglass jacket with stainless-steel snaps that protects components from temperatures up to 464°F. |

| Closure | Stainless Steel Reinforced Kevlar Thread | Toothed Zipper (High-Temp Brass) | Stainless Steel Snaps |

| RoHS | RoHS-10 | ||

| Abrasion Resistance | Good | Good | |

| Installation Type | Pull-Through | Wrap-Around | |

| Purpose | Sleeve | EMI Shielding | |

| Min Temperature | Extreme | Moderate | Extreme |

| Minimum Operating Temperature | -58°F | -32°F | -58°F |

| Max Temperature | Extreme | Moderate | |

| Maximum Operating Temperature | 1022°F | 399°F | 464°F |

| Flexibility | Better | ||

| View | View | View |

ZTT® (ALS-5) Heat Reflect Pull-Through Cable Sleeve

A lightweight, highly flexible, pull-through thermal barrier sleeve that offers complete protection of components inside from temperatures up to 350°F.

Drawing Number(s): ZT17-09-004

Selected Part Number: ZT17-09-004-0.5

Features

Benefits

ZTT® (ALS-5) Heat Reflect Pull-Through Cable Sleeve

ZTT® (ALS-5) Heat Reflect Pull-Through Cable Sleeve

MATERIAL SPECIFICATIONS