EMI-101 Series Part 3 - Magnetic and Shielding Interference Problem Solutions

Preface | Part 1 | Part 2 | Part 3 | Part 4 | Part 5 | Conclusion

PART 3

You’ll need to determine the type of interference problem you have, whether it’s Magnetic or Electric, then you can begin exploring possible solutions.

If you have identified your interference problem as a Magnetic Field (H-Field) problem, you should consider a reorientation of your system components. Distance and cable orientation could virtually eliminate the problem. Although undesirable and time consuming, the overall cost of relocating and orientating will generally outweigh the high cost of procuring Mu-Metal magnetic shield material. Mu-Metal shields are made of 80% Nickel and they work by absorbing the magnetic field lines and dissipating the energy off as heat. As such, Mu-Metal shielding materials are generally very expensive, bulky (thick) and heavy. They generally have very limited to no flexibility as well. These characteristics make them highly undesirable in today’s systems where thin, lightweight and flexible package design is the goal.

Electric Shields

If you have identified your interference problem as an Electric Field (E-Field) problem, then there are a multitude of shielding materials and options available to resolve these kinds of issues. Ninety-five percent of all EMI problems tend to be Electric Field (E-Field) related. Materials exist which can deal with low to very high frequency interference problems and survive exposed to severe environmental conditions as well. Unlike the H-field shield materials discussed above, E-field shield materials are generally economical, thin, lightweight and flexible.

E-field shields work in two ways; some of the incoming wave energy is simply reflected back into the environment and some of it is shunted to ground when an electric charge begins to build up on the conductive shield via the ground termination.

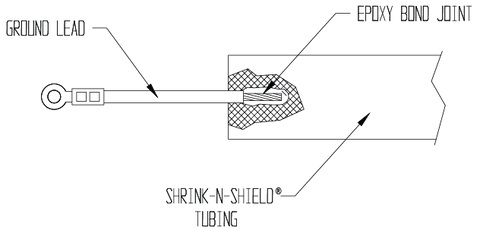

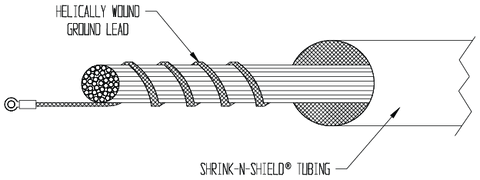

Although, often overlooked, proper grounding is very important to achieving a high-performance EMI shielding solution. When a conductive shield material is applied over the high dielectric insulation of electrical wires and cables a capacitor is created. A capacitor is simply two conductive materials separated by an insulator. If the outer conductive EMI shield material has no place to bleed the incoming E-field wave energy and the surface is allowed to continue to build up a significant charge potential, then at some point the energy on the outer surface will collapse and couple with the primary conductor of the wiring that you are trying to protect. This pulse of energy onto the primary wire conductor will cause a momentary energy spike down the conductor. This condition may simply create a momentary hiccup in the system, or it may seriously damage sensitive electronic circuits. It is very important to provide a ground connection to any EMI shield.

On the flip side, more is not necessarily better! Grounding both ends of an EMI shield can create a phenomenon known as ground looping. This is a system specific problem and it is difficult to know if grounding both ends of an EMI shield will create it or not. An EMI shield does not work better with both ends grounded versus a shield that is grounded only at one end. If you choose to ground both ends of an EMI shield and suddenly the problem you were trying to solve becomes worse than before you applied the shield, you most likely have a ground loop condition. Simply disconnecting one of the ground terminations will solve this problem.

In general, it is far safer to plan to ground one end of the EMI shield and let the opposite end float. The shield performance will be just as good.

Zippertubing® offers a wide variety of EMI shielding options whether you are in need of heat-shrink, jacket, tape, wrap or even a custom solution specific for your application.