Overview

- PVC-coated nylon fabric is military grade with meeting Mil-C-20696 / Mil-PRF-20696, Type II, Class 2

- Pressure track closure offers ability to quickly install and access components as needed

- The 7” diameter option has a National Stock Number (NSN) for easy procurement

Zip-On® (VNH) combines a military-grade jacket with a strong pressure track closure. The VNH jacketing is made of a nylon fabric with a flame-retardant PVC coating. The jacketing material meets Mil-C-20696, Type II, Class 2, making it a perfect choice for military and aerospace applications. The jacketing is also waterproof and abrasion resistant, which allows Zip-On® (VNH) to excel in harsh environments.

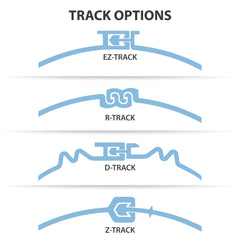

The Z-Track pressure track allows for easy re-entry to components due to its wraparound design, and it can be closed with our ZTZ-SP Plier tool for quick and easy installation. Z-Track is extruded from a flame-retardant PVC material. Its closes by utilizing an arrowhead-and-channel interlocking system that is heat sealed (RF sealed) to the VNH jacketing for a secure, long-lasting combination.

Zip-On® (VNH) is offered for diameters ranging from 0.375”to 7”, with the 7” diameter having an NSN; we also offer custom sizes upon request. Zip-On® (VNH) has an operational temperature range of -4°F to 171°F (-20°C to 77°C).

Zip-On® (VNH) is available with National Stock Numbers (NSN). This designation ensures that Zip-On® (VNH) meets the stringent standards required by military and government agencies, facilitating easy procurement and inventory management. The availability of Zip-On® (VNH) with NSNs underscores Zippertubing's commitment to quality and reliability in providing essential components for critical operations.

- Pressure track closure offers ability to access wires or cables as needed

- Waterproof, flame-retardant, abrasion-resistant jacketing

- Operational temperature range -4°F to 171°F (-20°C to 77°F)

- Wrap-around solution allows for easy installation and no disassembly required

- Ideal solution for tough conditions

- MIL-SPEC jacketing ideal for military and aerospace industries

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

VNH-23

- Mil-Spec:

- Durability:

- REACH:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Z-Track (PVC)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Guides

Zip-On® (VNH) Military-Grade Cable Bundling

A wrap-around cable bundling solution with a pressure track closure and an abrasion-resistant, waterproof, and flame-retardant jacketing.

Drawing Number(s): ZT99-16-064

Selected Part Number: ZT99-16-064-0.375-B

Features

Benefits

Zip-On® (VNH) Military-Grade Cable Bundling

Zip-On® (VNH) Military-Grade Cable Bundling

MATERIAL SPECIFICATIONS