Overview

- Perfect for industries where strength and abrasion protection are required

- Offers excellent flexibility and can be used in a multitude of combinations

- With the right configurations, this material will withstand just about anything

There are so many uses for Kevlar, and that is why The Zippertubing® Company now offers this material as an addition to their ever-growing inventory of products and materials. This ballistic-grade, woven fabric Kevlar material is resistant to wear and has a high breakage strength, all while maintaining its lightweight properties. It can be configured for round, flat or rectangular wire or cable bundles, as well as other custom component configurations, and can utilize many of our different closure options.

This combination of features makes it the perfect solution for abrasion protection jackets that wrap around your critical components. Kevlar can also be applied in multiple layers for use in safety or personal protection. To determine the number of layers needed for your chosen application, testing should be completed under the given circumstances you require.

Recommended Maximum Temperature Range for Long-Term Use in Air: 300°F to 350°F

*Please note that this material will degrade in UV light, and may not retain its original properties when immersed in liquid.

Features

- Operational temperature range of -320°F to 350°F

- Clean natural yellow appearance, perfect for military or industrial applications

Benefits

- A flexible, heat-resistant and strong synthetic fiber

- Can be sewn to other materials such as EMI shields and a variety of closures, including our hi-temp zippers

Specifications

Similar Materials

|

|

|

|

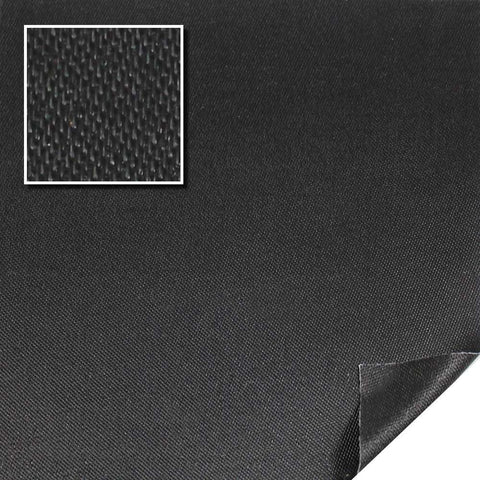

| NAME | RPA-14 - POLYURETHANE COATED ARAMID FABRIC - 14 MIL | RPH-14 - POLYURETHANE COATED POLYESTER FABRIC - 14 MIL | SRFG-32 - SILICONE COATED FIBERGLASS FABRIC - 32 MIL |

| DESCRIPTION | A Strong, Medium-Weight, Polyurethane Coated Aramid Fabric | A Flexible, Medium Weight, Polyurethane Coated Polyester Fabric, 14 mil | Heavy Duty Silicone Coated Fiberglass Jacket, 32 Mil |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | |

| Min Temperature | Low | Extreme | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -65°F |

| Max Temperature | Moderate | Moderate | Extreme |

| Maximum Operating Temperature | 302°F | 356°F | 449°F |

| Flexibility | Better | Better | |

| View | View | View |

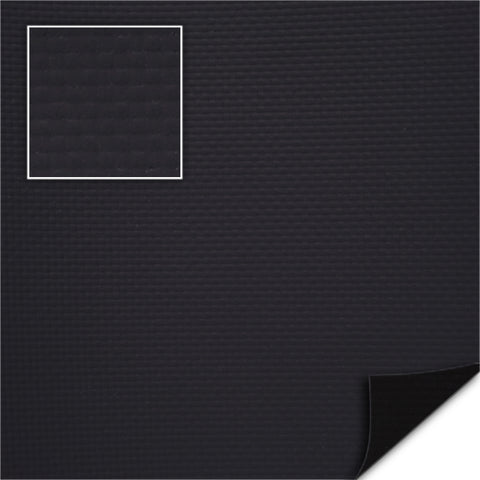

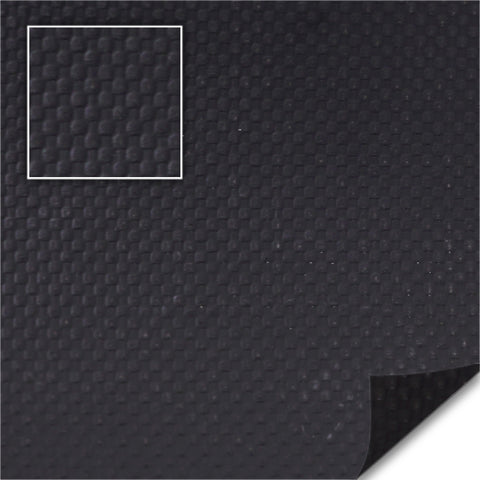

Kevlar (KWF-24) Ballistic-Grade Woven Fabric

Flexible and Rugged, Kevlar 24 Style 745, 24 Mil

Material Sprcification: 1131

- Perfect for industries where strength and abrasion protection are required

- Offers excellent flexibility and can be used in a multitude of combinations

- With the right configurations, this material will withstand just about anything

SPECIFICATIONS

DESCRIPTION

There are so many uses for Kevlar, and that is why The Zippertubing® Company now offers this material as an addition to their ever-growing inventory of products and materials. This ballistic-grade, woven fabric Kevlar material is resistant to wear and has a high breakage strength, all while maintaining its lightweight properties. It can be configured for round, flat or rectangular wire or cable bundles, as well as other custom component configurations, and can utilize many of our different closure options.

This combination of features makes it the perfect solution for abrasion protection jackets that wrap around your critical components. Kevlar can also be applied in multiple layers for use in safety or personal protection. To determine the number of layers needed for your chosen application, testing should be completed under the given circumstances you require.

Recommended Maximum Temperature Range for Long-Term Use in Air: 300°F to 350°F

*Please note that this material will degrade in UV light, and may not retain its original properties when immersed in liquid.