Cross-linked Polyolefin Copolymer

Material Specification: 6013

Raw materials are not available for standalone purchase; instead, they are intended to be integrated into a tailor-made, custom-engineered solution. Explore the possibilities below or contact an engineer to start your custom application today!

Overview

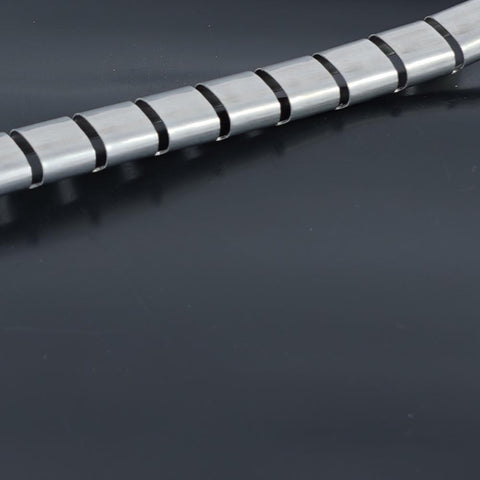

An adhesive lined electrical insulation sleeve that will shrink to a pre-determined size upon the application of heat and provide a watertight seal.

Specifications

Specifications subject to change without notice. All statements and technical information contained herein are based on tests we believe to be reliable, but the accuracy or completeness is not guaranteed under all circumstances. Before using Zippertubing® products, the user shall determine suitability for the intended use, and user assumes all responsibility for improper selection. Published attenuation values of Zippertubing® shielding have been verified by laboratory testing of the respective shielding materials. Actual installed attenuation values may differ due to installation techniques and final assembly operation parameters which are beyond the control of Zippertubing®. Actual attenuation values can only be determined by the end user testing the completed assembly. U.S. and International Patents and patents pending. © The Zippertubing® Company, Chandler, Arizona.

Similar Materials

|

|||

| NAME | POLYOLEFIN HEAT SHRINK TUBING | ||

| DESCRIPTION | |||

| RoHS | RoHS-10 | ||

| Abrasion Resistance | Best | ||

| Min Temperature | Extreme | ||

| Minimum Operating Temperature | -67°F | °F | °F |

| Max Temperature | Moderate | ||

| Maximum Operating Temperature | 275°F | °F | °F |

| Flexibility | Better | ||

| View |

Cross-linked Polyolefin Copolymer

Material Sprcification: 6013

WARNING: Raw materials are not sold separately, please contact the sales department for any special requirements.

SPECIFICATIONS

DESCRIPTION

An adhesive lined electrical insulation sleeve that will shrink to a pre-determined size upon the application of heat and provide a watertight seal.

Specifications subject to change without notice. All statements and technical information contained herein are based on tests we believe to be reliable, but the accuracy or completeness is not guaranteed under all circumstances. Before using Zippertubing® products, the user shall determine suitability for the intended use, and user assumes all responsibility for improper selection. Published attenuation values of Zippertubing® shielding have been verified by laboratory testing of the respective shielding materials. Actual installed attenuation values may differ due to installation techniques and final assembly operation parameters which are beyond the control of Zippertubing®. Actual attenuation values can only be determined by the end user testing the completed assembly. U.S. and International Patents and patents pending. © The Zippertubing® Company, Chandler, Arizona.