Overview

- VNH-23 jacketing offers rugged component protection

- SHX-4 shielding mesh provides good EMI protection

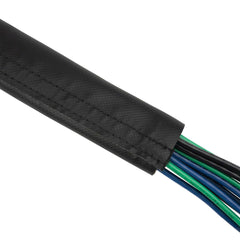

- Velcro-style hook-and-loop closure for quick installation

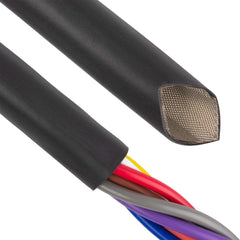

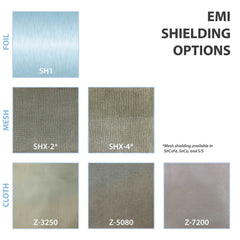

Hook-N-Shield® (VNH) combines durable jacketing with shielding mesh for component and EMI/RFI shielding protection. The outer jacketing, made from VNH-23 material, is flexible, PVC coated, military grade and flame retardant—ideal for applications in rugged environmental conditions. The inner jacketing has SHX-4 material for highly flexible EMI shielding.

Hook-N-Shield® (VNH) has a Velcro-style hook-and-loop closure for an easy, no-tools-required installation. This closure type also allows accessibility to the components inside when needed. There is an optional sewn-in braided ground wire for applications with such requirements. The operational temperature range of Hook-N-Shield® (VNH) is -65°F to 171°F (-54°C to 77°C).

- VNH-23 jacketing provides better flexibility and better abrasion resistance

- Hook-and-loop closure requires no tools for installation

- Operational temperature range of -65°F to 171°F (-54°C to 77°C)

- Wrap-around solution requires no disassembly or disconnection of components

- Flame-retardant, waterproof VNH-23 jacketing for use in rugged environments

- SHX-4 (SnCuFe) shielding mesh can withstand harsh conditions

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Material:

- Hook and Loop:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

VNH-23

- Mil-Spec:

- Durability:

- REACH:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Hook-and-Loop (Nylon)

SHX-4 (SnCuFe)

Nylon Thread

15 AWG Braided Ground Straps

5/8" Hook and Loop (Nylon)

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Hook-N-Shield® (VNH) Rugged EMI Shielded Cable Bundling

A wrap-around EMI shielding solution pairing a military-grade jacket with shielding mesh and a Velcro-style hook-and-loop closure.

Drawing Number(s): ZT12-13-004

Selected Part Number: ZT12-13-004-0.5-B-B

Features

Benefits

Hook-N-Shield® (VNH) Rugged EMI Shielded Cable Bundling

SHIELDING EFFECTIVENESS - SHX-4 (SnCuFe)

Hook-N-Shield® (VNH) Rugged EMI Shielded Cable Bundling

MATERIAL SPECIFICATIONS