Overview

- Available in six color options and a multitude of diameters with National Stock Numbers (NSN)

- Never disconnect or pull through another wire or cable again and water block it

- Excellent-anti abrasive, environmental, chemical, and electrical properties with resistance to most oils and fluids, mild acids, and alkalis

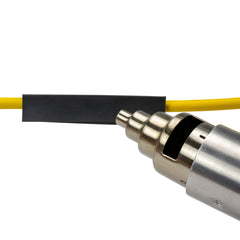

PRT® (ES-135) is our easy to install, wrap-around, military-grade PRT® heat shrink, combined with our high-temperature water blocking, hot-melt Z-Block™ (135). PRT® is a flame-retardant, abrasion-resistant, chemical-resistant, and fluid-resistant polyolefin heat shrink. PRT® is also RoHS compliant and UL-rated. PRT® repairs or re-jackets damaged components that cannot be disassembled. PRT® (ES-135) should be installed by using a standard heat gun that can reach 275°F (135°C).

Z-Block™ (135) is a high-temperature hot-melt adhesive tape that blocks and seals wires from fluids, oils, and greases. Z-Block™ (135) creates an environmental seal that will prevent fluids from damaging or penetrating components and can withstand temperatures of up to 275°F. Z-Block™ (135) is also RoHS compliant.

Pairing PRT® with Z-Block™ (135) creates the perfect solution for wires or cables exposed to fluids, and need repair or a durable jacket to prevent damage from occurring. PRT® (ES-135) comes in a standard 50-foot roll that can be cut to any desired length, offering versatility for application. PRT® (ES-135) is engineered for diameters ranging from 0.04” to 1.87”, with custom sizes available upon request. PRT® (ES-135) can also be customized with having a range of color options available for applications that may need color-coding. The operational temperature range is -67°F to 275°F (-55°C to 135°C). We also offer PRT® (ES-100), which has a lower temperature range of up to 212°F.

PRT® (ES-135) is available with National Stock Numbers (NSN). This designation ensures that PRT® (ES-135) meets the stringent standards required by military and government agencies, facilitating easy procurement and inventory management. The availability of PRT® (ES-135) with NSNs underscores Zippertubing's commitment to quality and reliability in providing essential components for critical operations.

- Comes in standard 50-foot roll that can be easily cut to any desired length

- Ideal for repairing damaged wires that also needs protection from water

- Operational temperature range is -67°F to 275°F (-55°C to 135°C)

- Utilizes a high-temperature hot-melt adhesive

- Military-grade, wrap-around heat shrink

- Available in custom sizes and colors upon request

Product Data

| Diameter - After Shrink | ||||

|---|---|---|---|---|

| 0.040" - 0.075" (#01) | 0.25" - 0.37" (#09) | 0.75" - 0.87" (#17) | 1.25" - 1.37" (#25) | 1.75" - 1.87" (#33) |

| 0.076" - 0.125" (#03) | 0.38" - 0.49" (#11) | 0.88" - 0.99" (#19) | 1.38" - 1.49" (#27) | |

| 0.126" - 0.174" (#05) | 0.50" - 0.62" (#13) | 1.0" - 1.12" (#21) | 1.50" - 1.62" (#29) | |

| 0.175" - 0.250" (#07) | 0.63" - 0.74" (#15) | 1.13" - 1.24" (#23) | 1.63" - 1.74" (#31) |

Specifications

Overall Performance

- Cable Diameter After Shrinkage:

- Closure:

- Environmental Seal:

- Material:

- Heat Shrink Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shrink Ratio:

- Water Blocking Type:

Polyolefin

- Mil-Spec:

- REACH:

- Dielectric Strength:

- Elongation:

- Flammability:

- Fungicide:

- Longitudinal Shrinkage:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

- Specific Gravity:

- Outgasssing (%TML):

- Outgassing (%CVCM):

- Outgassing (%WVR):

Tape (Specialty Surface)

Polyamide Hot Melt (135)

- REACH:

- Abrasion Resistance:

- Elongation:

- Flexibility:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Water Absorption:

- RoHS:

- Shelf Life:

- Softening Temp:

- Softening Temp Variance:

Similar products

|

|

||

| NAME | PRT® MIL-SPEC WRAP-AROUND HEAT SHRINK TUBING | SHRINK-N-REPAIR® (M) WRAP-AROUND HEAT SHRINK | |

| DESCRIPTION | A wrap-around heat shrink made from MIL-SPEC tubing that repairs electrical systems and assembled components and is resistant to abrasion and chemicals. | A wrap-around, abrasion-resistant, fluid-resistant heat shrink that repairs wires or cables with diameters up to 0.5”. | |

| Closure | Tape (Specialty Surface) | Tape (Specialty Surface) | |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | Best | |

| Installation Type | Wrap-Around | Wrap-Around | |

| Purpose | Wire Repair | Wire Repair | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -67°F | |

| Max Temperature | Moderate | Low | |

| Maximum Operating Temperature | 275°F | 275°F | |

| Flexibility | |||

| View | View |

Guides

PRT® (ES-135) Water-Blocking Wrap-Around Heat Shrink

A wrap-around, military-grade heat shrink paired with a high-temperature water blocking, hot-melt adhesive that protects against harsh environmental conditions.

Drawing Number(s): ZT03-04-010

Selected Part Number: ZT03-04-010-11-X600.0

Features

Benefits

PRT® (ES-135) Water-Blocking Wrap-Around Heat Shrink

PRODUCT DATA

| Diameter - After Shrink | ||||

|---|---|---|---|---|

| 0.040" - 0.075" (#01) | 0.25" - 0.37" (#09) | 0.75" - 0.87" (#17) | 1.25" - 1.37" (#25) | 1.75" - 1.87" (#33) |

| 0.076" - 0.125" (#03) | 0.38" - 0.49" (#11) | 0.88" - 0.99" (#19) | 1.38" - 1.49" (#27) | |

| 0.126" - 0.174" (#05) | 0.50" - 0.62" (#13) | 1.0" - 1.12" (#21) | 1.50" - 1.62" (#29) | |

| 0.175" - 0.250" (#07) | 0.63" - 0.74" (#15) | 1.13" - 1.24" (#23) | 1.63" - 1.74" (#31) |

PRT® (ES-135) Water-Blocking Wrap-Around Heat Shrink

MATERIAL SPECIFICATIONS