Overview

- Never disconnect or pull through another wire or cable again

- Excellent anti abrasive, environmental, chemical, and electrical properties with resistance to most oils and fluids, mild acids, and alkalis

- Many PRT® sizing variations also offer National Stock Numbers (NSN)

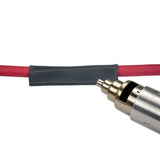

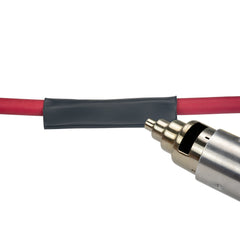

PRT® is a wrap-around heat shrink that is engineered for the most rugged of conditions. Made of MIL-SPEC tubing that is flame-retardant, abrasion-resistant, chemical-resistant, and fluid-resistant, PRT® is the perfect choice for repairing or re-jacketing components that have been damaged and can’t be easily removed for replacement. PRT® eliminates the hassle of downtime and can be wrapped around and heat-sealed on the spot. PRT® can be cut to any desired length, is ideal for indoor or outdoor environments, and is RoHS compliant and UL-rated.

PRT® has passed all short-term submersion tests and holds up against the harshest fluids, including jet fuels, Skydrol and many others.

PRT® is being utilized in the automotive and aerospace industries and has been used by the military since 1998. Fit for all industries, from commercial to industrial, PRT® can be applied like a traditional non-split heat shrink and requires only a heat gun for installation.

PRT® is offered in size ranges for diameters from 0.09” to 1.87” and has an operational temperature range of -67°F to 275°F (-55°C to 135°C).

PRT is available with National Stock Numbers (NSN). This designation ensures that PRT meets the stringent standards required by military and government agencies, facilitating easy procurement and inventory management. The availability of PRT with NSNs underscores Zippertubing's commitment to quality and reliability in providing essential components for critical operations.

- Handles up to 17,500 volts and is resistant to harsh fluids

- Repair and re-jacket components without disassembly

- Operational temperature range of -67°F to 275°F (-55°C to 135°C)

- Made from MIL-SPEC tubing that is flame-retardant

- Available in six color options and 16 diameter range sizes

- Built for rugged environmental conditions where traditional heat shrink won’t last

Specifications

Overall Performance

- Cable Diameter After Shrinkage:

- Closure:

- Material:

- Flammability:

- Heat Shrink Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shrink Ratio:

Polyolefin

- Mil-Spec:

- REACH:

- Dielectric Strength:

- Elongation:

- Flammability:

- Fungicide:

- Longitudinal Shrinkage:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

- Specific Gravity:

- Outgasssing (%TML):

- Outgassing (%CVCM):

- Outgassing (%WVR):

Tape (Specialty Surface)

Similar products

|

|

||

| NAME | SHRINK-N-REPAIR® (M) WRAP-AROUND HEAT SHRINK | PRT® (ES-135) WATER-BLOCKING WRAP-AROUND HEAT SHRINK | |

| DESCRIPTION | A wrap-around, abrasion-resistant, fluid-resistant heat shrink that repairs wires or cables with diameters up to 0.5”. | A wrap-around, military-grade heat shrink paired with a high-temperature water blocking, hot-melt adhesive that protects against harsh environmental conditions. | |

| Closure | Tape (Specialty Surface) | Tape (Specialty Surface) | |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | Best | |

| Installation Type | Wrap-Around | Wrap-Around | |

| Purpose | Wire Repair | Water Blocking | |

| Min Temperature | Moderate | Extreme | |

| Minimum Operating Temperature | -67°F | -67°F | |

| Max Temperature | Low | Moderate | |

| Maximum Operating Temperature | 275°F | 275°F | |

| Flexibility | |||

| View | View |

Guides

PRT® MIL-SPEC Wrap-Around Heat Shrink Tubing

A wrap-around heat shrink made from MIL-SPEC tubing that repairs electrical systems and assembled components and is resistant to abrasion and chemicals.

Drawing Number(s): ZT98-04-016

Selected Part Number: ZT98-04-016-0-B-X600.0

Features

Benefits

PRT® MIL-SPEC Wrap-Around Heat Shrink Tubing

PRT® MIL-SPEC Wrap-Around Heat Shrink Tubing

MATERIAL SPECIFICATIONS