Raw materials are not available for standalone purchase; instead, they are intended to be integrated into a tailor-made, custom-engineered solution. Explore the possibilities below or contact an engineer to start your custom application today!

Overview

- Extremely durable

- Resistant to abrasion, punctures, and tears

- Very flexible

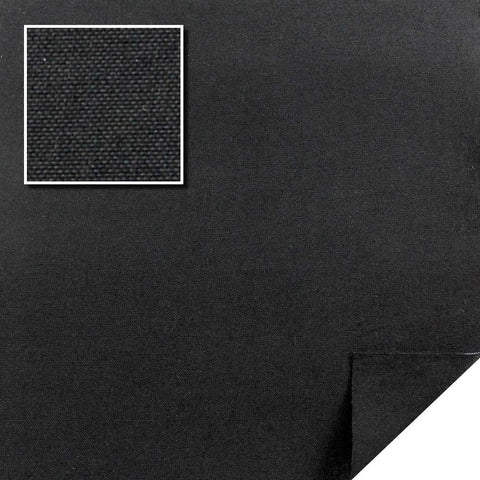

Ballistic Nylon is a medium-weight fabric made from high-strength nylon fibers woven in a distinctive basketweave pattern, known for its exceptional toughness and durability. Originally developed during World War II for military applications, this fabric was engineered to provide a superior level of protection for soldiers.

One of the standout features of Ballistic Nylon is its remarkable resistance to abrasion, punctures, and tears, making it an ideal material for products exposed to rugged conditions. Its tight weave structure also provides substantial resistance to moisture, mildew, and UV damage, contributing to its longevity and reliability even in harsh environments.

The fabric maintains an excellent balance between strength and flexibility, allowing it to be used in a variety of applications. Ballistic Nylon meets stringent military specifications, including MIL-C-12369, ensuring it adheres to rigorous standards of performance, resilience, and quality required for military use. Its legacy of durability and protection has made it a trusted material not just in defense, but also in civilian applications where robustness is paramount.

Features

- High-Strength Nylon Fibers: Made from robust nylon fibers that provide excellent tensile strength.

- Puncture and Tear Resistance: High resistance to sharp objects and tearing, ensuring long-lasting performance.

Benefits

- Enhanced Durability: Prolongs the life of products, reducing the need for frequent replacements and repairs.

- Weather Resistance: Performs well in various weather conditions, resisting moisture and preventing mold growth, which is critical for outdoor use.

Specifications

Similar Materials

|

|

|

|

| NAME | NYLON SPANDEX WOVEN FABRIC | KEVLAR (KWF-24) BALLISTIC-GRADE WOVEN FABRIC | TREVIRA CANVAS FABRIC - 15 MIL |

| DESCRIPTION | A lightweight, nylon spandex blend fabric that is abrasion resistant and has good stretch and elasticity. | Flexible and Rugged, Kevlar 24 Style 745, 24 Mil | Lightweight Canvas Jacketing, 15 Mil |

| RoHS | RoHS-10 | ||

| Abrasion Resistance | Better | Good | |

| Min Temperature | Extreme | Extreme | Moderate |

| Minimum Operating Temperature | -40°F | -321°F | °F |

| Max Temperature | Low | Moderate | Moderate |

| Maximum Operating Temperature | 176°F | 350°F | °F |

| Flexibility | Best | Best | |

| View | View | View |

Ballistic Nylon Fabric

Medium weight fabric comprised of nylon fibers in a basketweave pattern. This fabric provides a good amount of strength, durability, and flexibility.

Material Sprcification: 1131

- Extremely durable

- Resistant to abrasion, punctures, and tears

- Very flexible

SPECIFICATIONS

DESCRIPTION

Ballistic Nylon is a medium-weight fabric made from high-strength nylon fibers woven in a distinctive basketweave pattern, known for its exceptional toughness and durability. Originally developed during World War II for military applications, this fabric was engineered to provide a superior level of protection for soldiers.

One of the standout features of Ballistic Nylon is its remarkable resistance to abrasion, punctures, and tears, making it an ideal material for products exposed to rugged conditions. Its tight weave structure also provides substantial resistance to moisture, mildew, and UV damage, contributing to its longevity and reliability even in harsh environments.

The fabric maintains an excellent balance between strength and flexibility, allowing it to be used in a variety of applications. Ballistic Nylon meets stringent military specifications, including MIL-C-12369, ensuring it adheres to rigorous standards of performance, resilience, and quality required for military use. Its legacy of durability and protection has made it a trusted material not just in defense, but also in civilian applications where robustness is paramount.