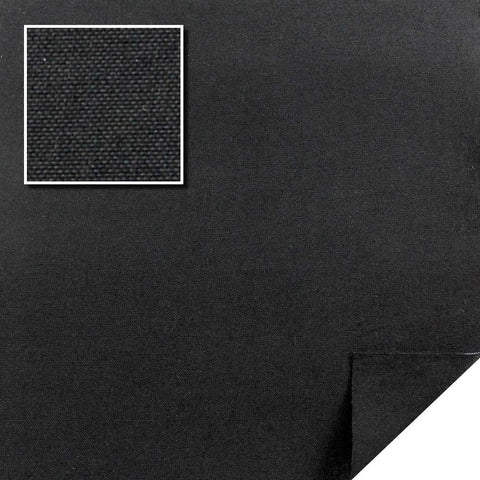

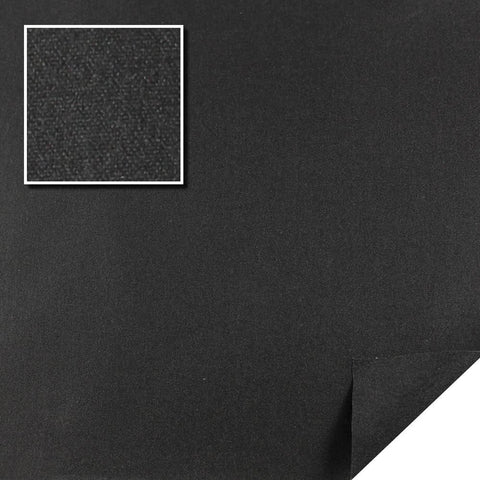

Nylon Spandex Woven Fabric

A lightweight, nylon spandex blend fabric that is abrasion resistant and has good stretch and elasticity.

Raw materials are not available for standalone purchase; instead, they are intended to be integrated into a tailor-made, custom-engineered solution. Explore the possibilities below or contact an engineer to start your custom application today!

Overview

- Lightweight, nylon spandex blend fabric

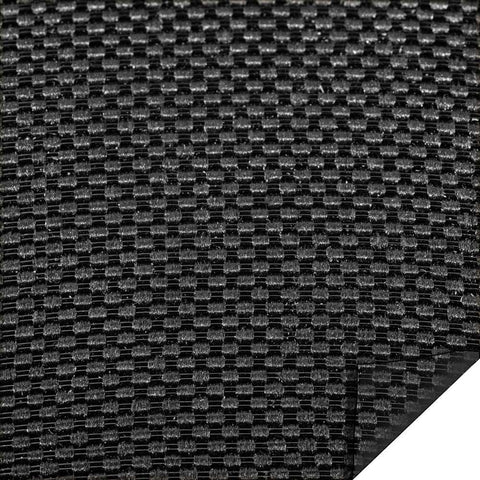

- Abrasion resistant

- Spandex fibers provide good stretch and elasticity

Nylon Spandex Woven Fabric is made from a blend of nylon and spandex fibers. The fabric provides abrasion protection as well as good stretch and elasticity due to its spandex content. Nylon Spandex Woven Fabric has an operational temperature range of -40°F to 176°F (-40°C to 80°C).

Specifications

Similar Materials

|

|

|

|

| NAME | TREVIRA CANVAS FABRIC - 15 MIL | FRC-15 CANVAS FABRIC - 15 MIL | POLYESTER (PET) MATERIAL |

| DESCRIPTION | Lightweight Canvas Jacketing, 15 Mil | Lightweight Multi-Purpose Canvas Jacket, 15 Mil | An abrasion-resistant, flexible polyester material that is self-extinguishing. |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Good | Better | |

| Min Temperature | Moderate | Moderate | Moderate |

| Minimum Operating Temperature | °F | -22°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | °F | 140°F | 302°F |

| Flexibility | Best | Best | |

| View | View | View |

Nylon Spandex Woven Fabric

A lightweight, nylon spandex blend fabric that is abrasion resistant and has good stretch and elasticity.

Material Sprcification: 1138

- Lightweight, nylon spandex blend fabric

- Abrasion resistant

- Spandex fibers provide good stretch and elasticity

SPECIFICATIONS

DESCRIPTION

Nylon Spandex Woven Fabric is made from a blend of nylon and spandex fibers. The fabric provides abrasion protection as well as good stretch and elasticity due to its spandex content. Nylon Spandex Woven Fabric has an operational temperature range of -40°F to 176°F (-40°C to 80°C).