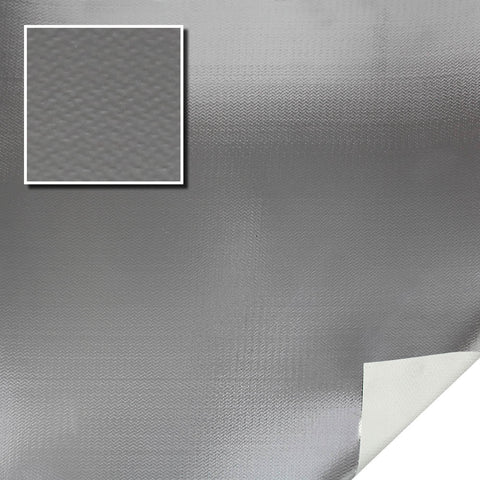

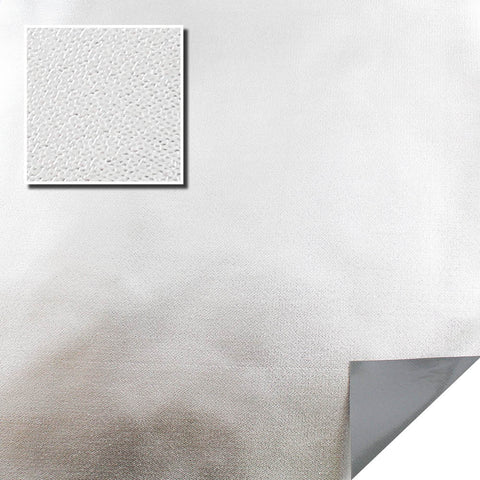

ALK-19 Heat Reflective Woven Kevlar Fabric

High Strength Heat Reflective Woven Kevlar Fabric, Up to 177°C

Raw materials are not available for standalone purchase; instead, they are intended to be integrated into a tailor-made, custom-engineered solution. Explore the possibilities below or contact an engineer to start your custom application today!

Overview

- Aluminized Aramid (Kevlar) Fabric

- Moderately High Temperature Heat Reflective Cloth

- Custom Shapes Available

- Many Closures Available

ALK-19 is an Aluminized woven Aramid Cloth (Kevlar) with very high structural strength, yet is flexible and capable of withstanding temperatures of 350°F (177°C) continuously. Ideal in applications where the jacket must act as the structural member for a cable assembly under high heat conditions.

Specifications

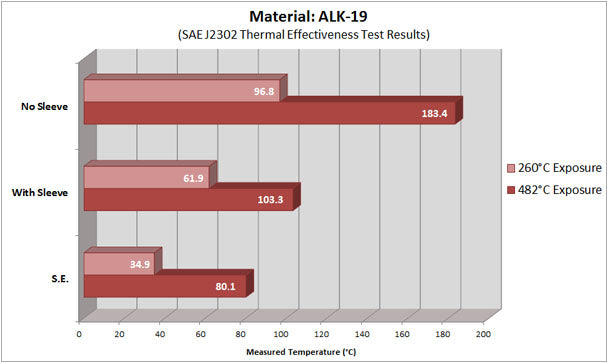

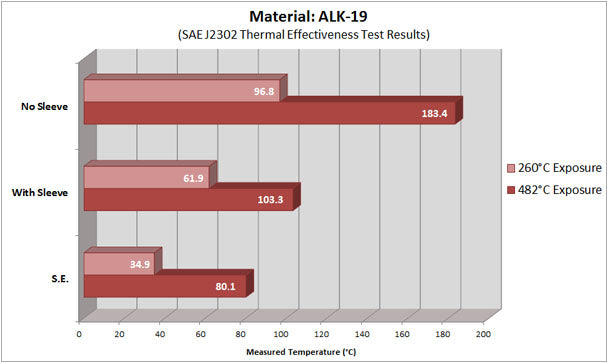

Thermal Effectiveness

Similar Materials

|

|

|

|

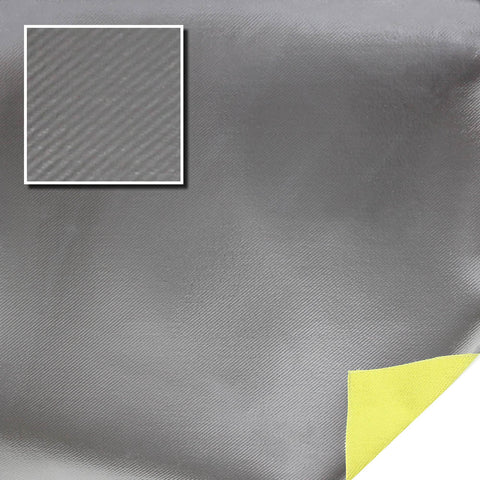

| NAME | ALP-500 ALUMINIZED FIBERGLASS HEAT SHIELDING | ALS-5 FLEXIBLE ALUMINIZED FIBERGLASS HEAT SHIELDING | ALSR-15 ALUMINIZED SILICONE COATED FIBERGLASS |

| DESCRIPTION | Aluminized Fiberglass Heat Barrier, Up To 180°C | A thin, highly flexible aluminized fiberglass heat shielding material; shields up to 350°F (177°C). | Mil-Spec Aluminized Silicone Coated Fiberglass, Up to 260°C |

| RoHS | RoHS-10 | ||

| Abrasion Resistance | Best | Good | Better |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -58°F | -58°F | -67°F |

| Max Temperature | Moderate | Moderate | Extreme |

| Maximum Operating Temperature | 350°F | 350°F | 500°F |

| Flexibility | Better | Best | Best |

| View | View | View |

ALK-19 Heat Reflective Woven Kevlar Fabric

High Strength Heat Reflective Woven Kevlar Fabric, Up to 177°C

Material Sprcification: 1205

- Aluminized Aramid (Kevlar) Fabric

- Moderately High Temperature Heat Reflective Cloth

- Custom Shapes Available

- Many Closures Available

SPECIFICATIONS

DESCRIPTION

ALK-19 is an Aluminized woven Aramid Cloth (Kevlar) with very high structural strength, yet is flexible and capable of withstanding temperatures of 350°F (177°C) continuously. Ideal in applications where the jacket must act as the structural member for a cable assembly under high heat conditions.

ALK-19 Heat Reflective Woven Kevlar Fabric

Thermal Effectiveness