Raw materials are not available for standalone purchase; instead, they are intended to be integrated into a tailor-made, custom-engineered solution. Explore the possibilities below or contact an engineer to start your custom application today!

Overview

- Ideal closure option for clean rooms and the medical industry*

- Extruded thermoplastic, polyurethane material

- Flame retardant

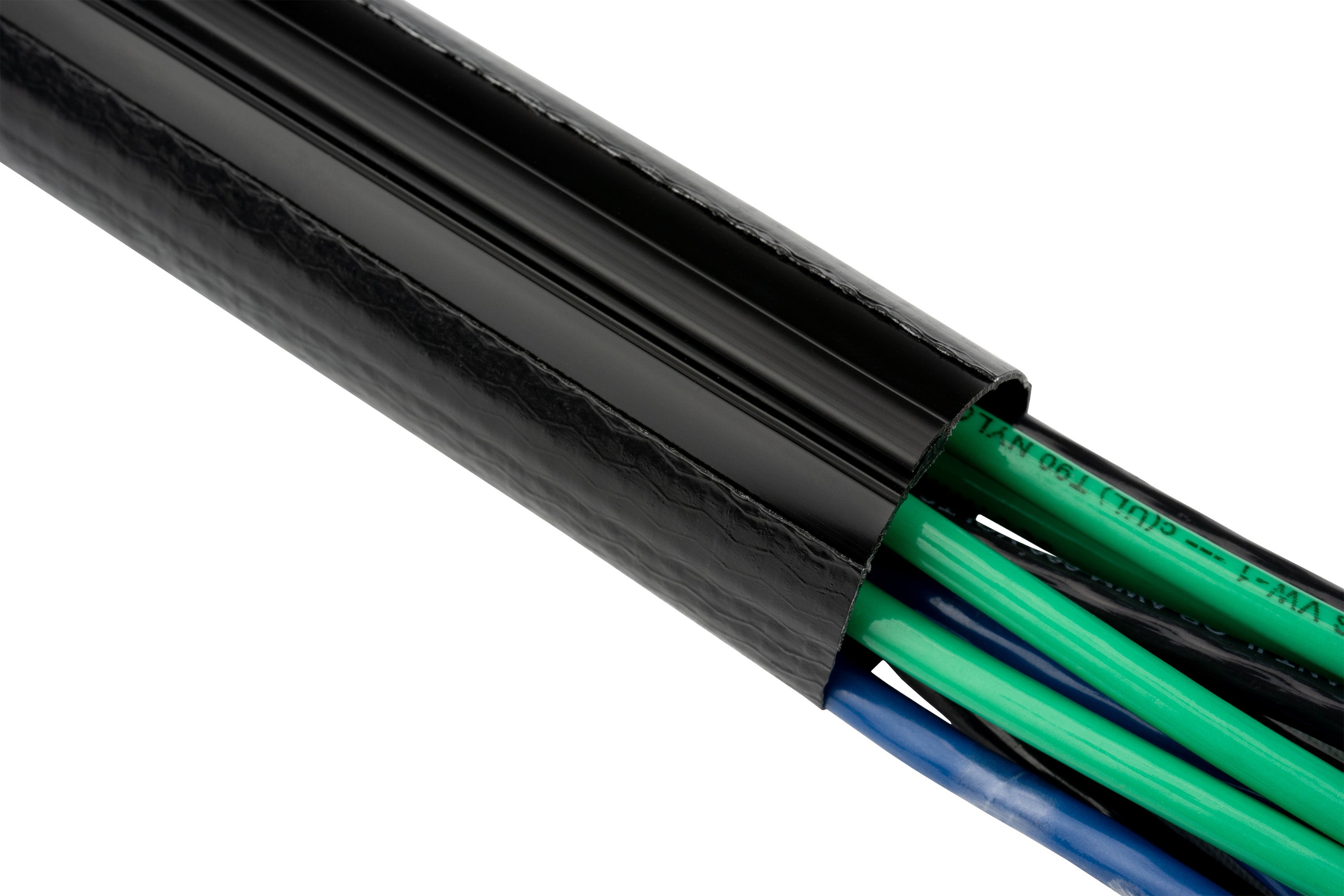

EZ-Track™ (TPU) is an extruded pressure track closure made of a thermoplastic polyurethane material. The arrowhead and channel interlocking system provides a seal around wires and cables. The white, halogen-free track is perfect for clean rooms and the medical industry. The EZ-Track™ (TPU) pressure track can be used for 0.4375” diameters as a single-extruded product, or can be paired with the TPU jacketing for wires and cables with larger diameters. The EZ-Track™ (TPU) can be closed with the SL-EZ Slider tool for smaller runs, and the ZTEZ-SP Plier for longer runs. The operational temperature range of EZ-Track™ (TPU) is -40°F to 257°F (-40°C to 125°C).

*EZ-Track™ (TPU) is not manufactured using a clean room in sterile conditions, but with the right procedures, it could be used in the medical field, including in hospitals, operating rooms, trauma centers, and emergency rooms.

Specifications

Guides

How to install EZ-Track™

As its name implies, EZ-Track® is easy to install. Learn about track closure versus bend location with thes...

Read more

Track Closure vs Bend Location for all Zippertubing tracks

Learn how to properly install Zip-On and Zip-Shield Zippertubing® products. In this article, we also highli...

Read more

EZ-Track (TPU) Extruded Pressure Track

Flame-retardant, thermoplastic polyurethane extruded arrowhead and channel closure system.

Material Sprcification: 2020

- Ideal closure option for clean rooms and the medical industry*

- Extruded thermoplastic, polyurethane material

- Flame retardant

SPECIFICATIONS

DESCRIPTION

EZ-Track™ (TPU) is an extruded pressure track closure made of a thermoplastic polyurethane material. The arrowhead and channel interlocking system provides a seal around wires and cables. The white, halogen-free track is perfect for clean rooms and the medical industry. The EZ-Track™ (TPU) pressure track can be used for 0.4375” diameters as a single-extruded product, or can be paired with the TPU jacketing for wires and cables with larger diameters. The EZ-Track™ (TPU) can be closed with the SL-EZ Slider tool for smaller runs, and the ZTEZ-SP Plier for longer runs. The operational temperature range of EZ-Track™ (TPU) is -40°F to 257°F (-40°C to 125°C).

*EZ-Track™ (TPU) is not manufactured using a clean room in sterile conditions, but with the right procedures, it could be used in the medical field, including in hospitals, operating rooms, trauma centers, and emergency rooms.