Overview

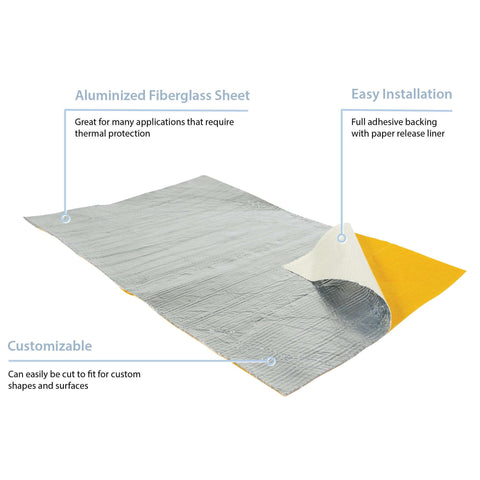

- Can be cut to any shape or size desired

- Polycoated paper release liner for easy application

- Can protect from continuous ambient temperatures up to 356°F, and a maximum radiant temperature of 995°F

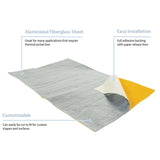

HeatReflect® (AFA) is an aluminized fiberglass sheet with a full adhesive backing. This heat barrier solution can be used for a wide range of applications. Since the entire back of HeatReflect® (AFA) is adhesive, it can be cut with standard scissors to any size or shape desired.

HeatReflect® (AFA) is utilized in the automotive industry, such as on cars, trucks, RVs and motorcycles, due to the flexibility and ease of application. You can install HeatReflect® (AFA) right on the job without the need to disassemble or take apart. HeatReflect® (AFA) is also desired for residential applications, such as on walls adjacent to kitchen appliances like ovens, microwaves and refrigerators, with protecting from high heat that tends to be emitted from such equipment. Applying HeatReflect® (AFA) where heat needs reflection can save on replacement costs or significant damage. The acrylic adhesive is strong and provides a secure stick and seal. The adhesive is equipped with a paper release liner that allows for a quick and clean installation.

HeatReflect® (AFA) is offered in a 12” by 36” piece, with custom widths and lengths available upon request. The operational ambient temperature range is -40°F to 356°F (-40°C to 180°C), and a maximum flash exposures of 995°F (535°C).

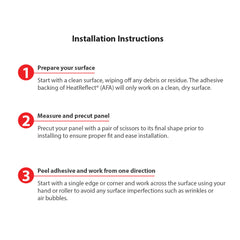

Instructions:

Prepare your surface- Start with a clean surface, wiping off any debris or residue. The adhesive backing of HeatReflect® (AFA) will only work on a clean, dry surface.

Measure and precut panel - Precut your panel with a pair of scissors to its final shape prior to installing to ensure proper fit and ease installation.

Peel adhesive and work from one direction - Start with a single edge or corner and work across the surface using your hand or roller to avoid any surface imperfections such as wrinkles or air bubbles.

- Versatile uses from automotive to residential

- Standard scissors can be used to cut any shape or size

- Can withstand 356°F continuous ambient temperature and 995°F radiant temperature

- Can be used in moderately high ambient temperature and extreme radiant temperature environments

- Full adhesive backing provides strong, secure stick and seal

- Paper release liner offers quick and clean installation

Specifications

Overall Performance

- Closure:

- Material:

- Height:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

AFA-55

- Weight:

- Closure:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Tensile Strength:

Similar products

|

|

|

|

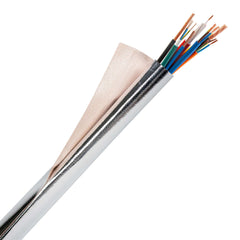

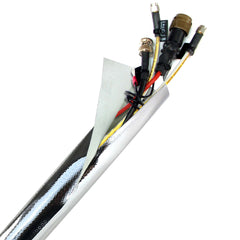

| NAME | HEAT-WRAP® (ALS-5) FLEXIBLE THERMAL REFLECTIVE WRAP | HEAT-WRAP® (ALP-500) HEAT RESISTANT WRAP | HEATREFLECT® (ALP) HEAT SHIELDING TAPE |

| DESCRIPTION | A lightweight, heat-shielding, wrap-around, adhesive-sealed solution that can be exposed to temperatures up to 300°F. | A durable, heat-shielding, wrap-around, adhesive-sealed solution that can be exposed to temperatures up to 300°F. | A medium-weight, aluminum-coated fiberglass heat shielding tape to protect from temperatures up to 300°F. |

| Closure | Tape (High Temperature) | Tape (High Temperature) | Tape (High Temperature) |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Good | Best | Best |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Tape |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -40°F | -40°F | -40°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 300°F | 300°F | 300°F |

| Flexibility | |||

| View | View | View |

Guides

HeatReflect® (AFA) Adhesive-Backed Heat Shielding

HeatReflect® (AFA) is a completely customizable heat shielding solution – the shapes and sizes for applications are endless.

Drawing Number(s): ZT19-15-002

Selected Part Number: ZT19-15-002-12.0-X36.0

Features

Benefits

HeatReflect® (AFA) Adhesive-Backed Heat Shielding

HeatReflect® (AFA) Adhesive-Backed Heat Shielding

MATERIAL SPECIFICATIONS