Overview

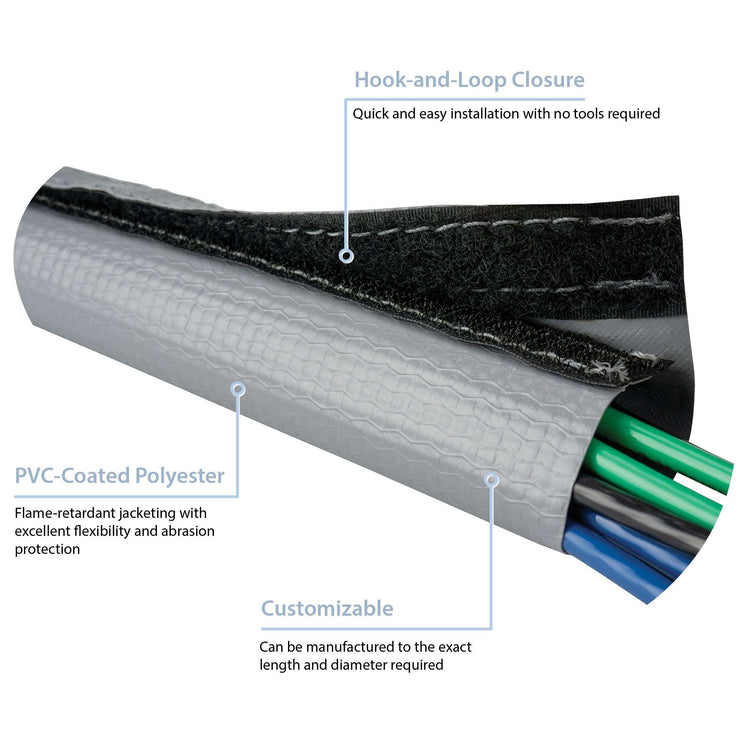

- Military-grade, lightweight and flexible PVL-10 jacketing that offers multiple color options

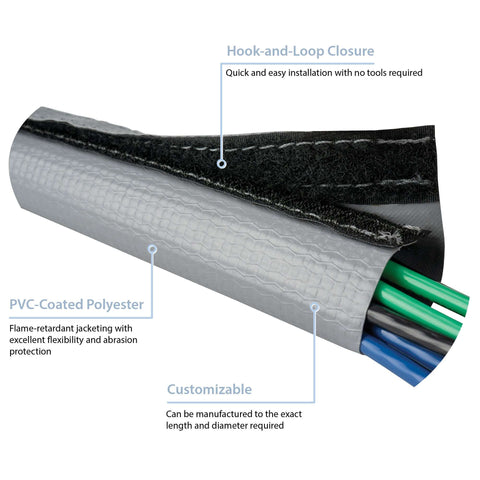

- Nylon hook-and-loop closure for quick and easy installation with no tools required

- Size options for diameters ranging from 0.5” to 8” with custom diameters and lengths available upon request

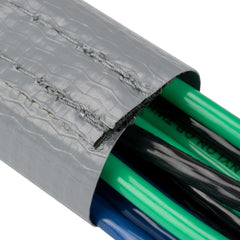

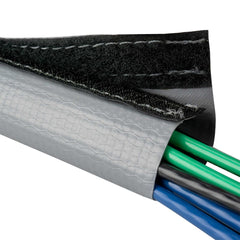

Hook-It® (PVL) is a durable yet lightweight component bundling and protecting solution that utilizes a Velcro-style, hook-and-loop closure. The PVL-10 jacketing is abrasion resistant and fire retardant, and it has high tear strength to prolong the protection of your wires or cables. Additionally, Hook-It® (PVL) is RoHS compliant. These properties make Hook-It® (PVL) ideal for applications that require a strong and durable solution.

The hook-and-loop closure is made from woven nylon. One side has stiff hooks, and the other has soft loops. When these two sides latch together, the closure is secure but can be easily pulled apart for access. The closure is sewn to the PVL-10 jacketing with nylon thread. For applications that may require re-entry or the ability to quickly and easily breakout wires or cables, Hook-It® (PVL) is the ideal solution.

Manufacturing facilities or environments that are exposed to harsh conditions can utilize Hook-It® (PVL) to manage and protect their components from abrasion damage. Hook-It® (PVL) is offered in diameter sizes from 0.5” to 8” with custom lengths available. It has an operational temperature range of -40°F to 180°F (-40°C to 82°C).

- No tools required for installation

- Wide variety of size options with custom sizes and lengths available

- Operational temperature ranges from -40°F to 180°F (-40°C to 82°C)

- Military-grade jacketing resistant to abrasions and tears

- Easy application with a Velcro-style, hook-and-loop closure

- Flexible and lightweight while still providing secure protection

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Material:

- Hook and Loop:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

PVL-10

- Mil-Spec:

- REACH:

- Chemical Resistance:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Hook-and-Loop (Nylon)

Nylon Thread

5/8" / 1"

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Hook-It® (PVL) PVC-Coated Polyester Cable Bundling

A PVC-coated, lightweight, fire-retardant and abrasion-resistant jacketing with a hook-and-loop closure.

Drawing Number(s): ZT97-13-004

Selected Part Number: ZT97-13-004-0.5-B

Features

Benefits

Hook-It® (PVL) PVC-Coated Polyester Cable Bundling

Hook-It® (PVL) PVC-Coated Polyester Cable Bundling

MATERIAL SPECIFICATIONS