Overview

- Flame-retardant, abrasion-resistant thermal barrier jacketing

- Hook-and-loop closure for easy installation

- Constructed with Kevlar thread for rugged conditions

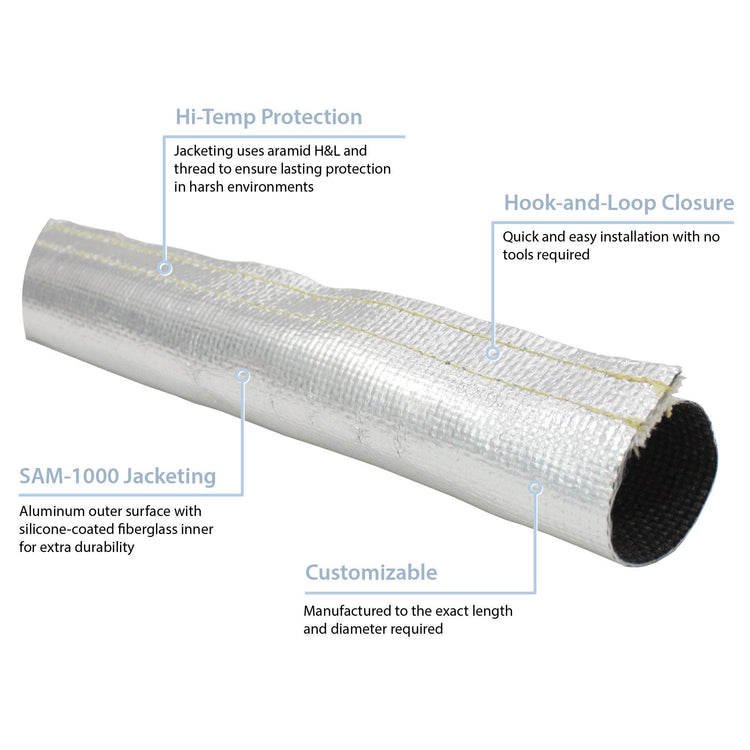

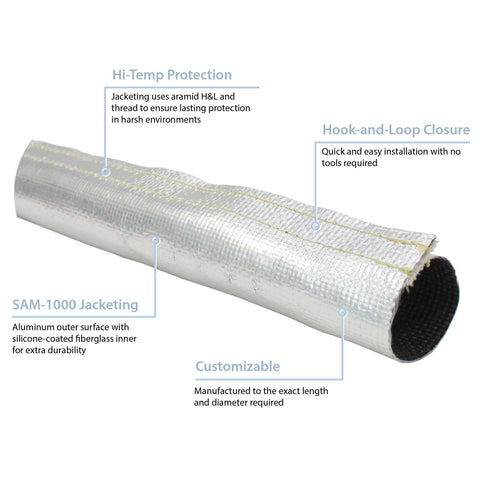

Hook-It® (SAM-1000) combines the convenience of a Velcro-style hook-and-loop closure with the thermal reflection capability of the SAM-1000 jacketing. The SAM-1000 material is a fiberglass cloth coated with silicone on one side and a reflective aluminum on the other. The jacketing is non-flammable and has good abrasion resistance. This heat shielding material is durable for applications that are in rugged environments or are exposed to harsh conditions.

The hook-and-loop material, made of Aramid and nylon, conforms to specification GSA A-A-55126, Type I, Class 2 and is flame retardant. This Velcro-style closure system allows for installation without any tools, and it can be easily peeled apart to access components inside and then quickly reengaged for a secure seal. The hook-and-loop material is sewn to the SAM-1000 jacketing with a Kevlar thread that can also handle high temperatures and rugged conditions.

Hook-It® (SAM-1000) is engineered for automotive and industrial applications due to the moderately high temperature shielding and the flexible, abrasion-resistant jacketing. If needed, you can cut Hook-It® (SAM-1000) to any length desired for versatility in uses*. Diameter options for Hook-It® (SAM-1000) range from 0.5” to 6”, with custom sizes available upon request. The operational temperature range is -50°F to 350°F (-46°C to 177°C).

*When trimming the length of any sewn product, we recommend sewing the cut ends. When cutting this product, we recommend using Kevlar thread to resew the ends to ensure the retention of the original thermal properties. If you wish to have custom cut lengths, Zippertubing® will cut to any desired requirements.

- Flame-retardant jacketing coated with reflective aluminum

- Wide range of diameters and custom sizes

- Operational temperature range of -50°F to 350°F (-46°C to 177°C)

- Shields from moderately high temperatures

- Wraps around wires or cables without the need of disconnection

- Durable jacketing that can handle rugged conditions

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Material:

- Hook and Loop:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

SAM-1000

- REACH:

- Chemical Resistance:

- Flammability:

- Thickness:

- Thickness Variance:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tear Strength:

Hook-and-Loop (Aramid)

Kevlar Thread

5/8" Hook and Loop (Aramid) White

Similar products

|

|

|

|

| NAME | ZTT® (ALR-550) HIGH TEMP PULL-THROUGH CABLE SLEEVE | ZIPPER-MESH (ALHTG-65) EMI & HEAT SHIELDED JACKETING | SNAP-GRIP® (SAM-1000) HEAT SHIELDED CABLE BUNDLING |

| DESCRIPTION | A pull-through, flexible heat shielding sleeve that protects components from continuous temperatures as high as 1,022°F. | An all-in-one, wrap-around solution combining the heat shielding of the ALHTG-65 with the EMI shielding of the knitted SHX-4 mesh and a brass zipper. | A heat shielding solution featuring a silicone, polymer-coated fiberglass jacket with stainless-steel snaps that protects components from temperatures up to 464°F. |

| Closure | Stainless Steel Reinforced Kevlar Thread | Toothed Zipper (High-Temp Brass) | Stainless Steel Snaps |

| RoHS | RoHS-10 | ||

| Abrasion Resistance | Good | Good | |

| Installation Type | Pull-Through | Wrap-Around | |

| Purpose | Sleeve | EMI Shielding | |

| Min Temperature | Extreme | Moderate | Extreme |

| Minimum Operating Temperature | -58°F | -32°F | -58°F |

| Max Temperature | Extreme | Moderate | |

| Maximum Operating Temperature | 1022°F | 399°F | 464°F |

| Flexibility | Better | ||

| View | View | View |

Hook-It® (SAM-1000) High-Temp Heat Shielding Sleeve

Durable silicone-coated fiberglass jacketing with a high-temperature, Velcro-style hook-and-loop closure.

Drawing Number(s): ZT17-13-006

Selected Part Number: ZT17-13-006-0.5

Features

Benefits

Hook-It® (SAM-1000) High-Temp Heat Shielding Sleeve

Hook-It® (SAM-1000) High-Temp Heat Shielding Sleeve

MATERIAL SPECIFICATIONS