Overview

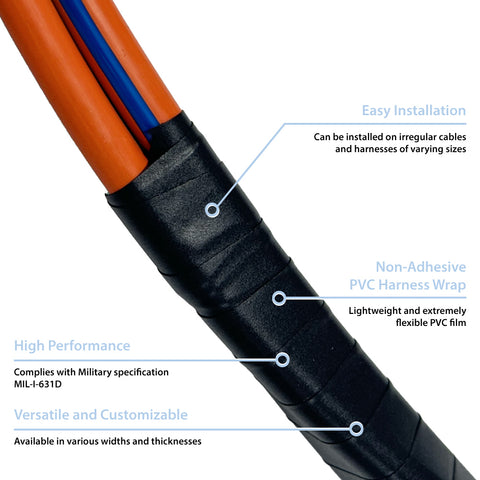

MIL-I-631 Tape is specially designed to meet the performance specifications of MIL-I-631D for flexible (nonrigid) electrical insulation with a synthetic-resin composition. Zippertubing's PVC MIL-I-631 Tape meets the requirements for Type F (polyvinyl chloride / PVC), Form T (Tape), Subform Ts (Sheet Tape), Grade A (General Purpose), Class I (Fungus Resistant). This military grade insulation tape is ideal for harness wrapping where protection is required but adhesive tapes cannot be used. This tape wrap will protect harnesses and cables, while avoiding adhesive failure or messy residue in high temperature areas.

MIL-I-631 Tape has been used by the military, Department of Defense (DoD) contractors, and harness manufacturers for decades. This tape is available in many different widths and thicknesses to fit the diameter of cable or harness that needs to be wrapped. Sometimes procured under NSNs or industry part numbers such as: 10001-2825437; 591-0087-012

- Available in various widths and thicknesses

- Non-adhesive tape wrap is ideal for harnesses that need long service life or may experience high temps

- Extremely flexible, durable, and flame-retardant

- Complies with requirements in military specification MIL-I-631D

- Trusted military cable harness protection method for decades

- Can be installed on irregular cables and harnesses of varying sizes

Specifications

Overall Performance

- Chemical Resistance:

- Dielectric Strength:

- Elongation:

- Material:

- Flame Retardant:

- Thickness:

- Thickness Variance:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Width:

- Tensile Strength:

- Mil-Spec:

63-08

- Mil-Spec:

- REACH:

- Copper Corrosion:

- Dielectric Volts/Mil:

- Dielectric Constant:

- Elongation:

- Volume Resistivity:

- Flame Retardant:

- Fungicide:

- Color:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Dissipation Factor:

- Tensile Strength:

63-10

- Mil-Spec:

- REACH:

- Copper Corrosion:

- Dielectric Volts/Mil:

- Dielectric Constant:

- Elongation:

- Volume Resistivity:

- Flame Retardant:

- Fungicide:

- Color:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Dissipation Factor:

- Tensile Strength:

63-20

- Mil-Spec:

- REACH:

- Copper Corrosion:

- Dielectric Volts/Mil:

- Elongation:

- Volume Resistivity:

- Flame Retardant:

- Fungicide:

- Color:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

MIL-I-631 Tape Non Adhesive Electrical Tape

Non-adhesive PVC harness wrap that complies with MIL-I-631 Type F, Form T, Subform Ts, grade A, Class I. Great for new harness builds and reworks alike. This flexible PVC tape meets this demanding military specification.

Drawing Number(s): ZT24-15-001

Selected Part Number: ZT24-15-001-1.0-B-X600.0

Features

Benefits

MIL-I-631 Tape Non Adhesive Electrical Tape

MIL-I-631 Tape Non Adhesive Electrical Tape

MATERIAL SPECIFICATIONS