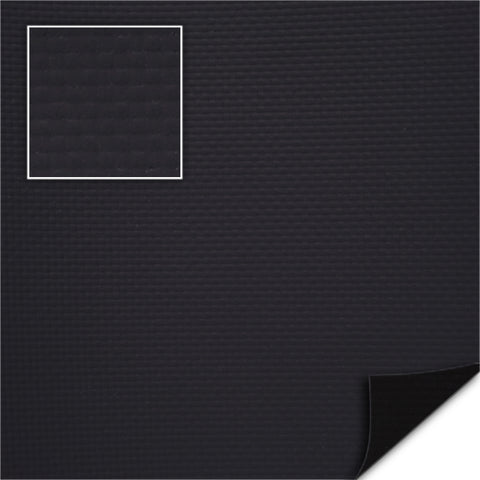

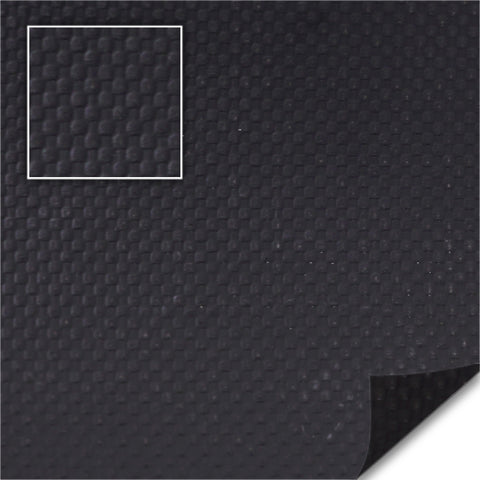

MLB PVC-Coated PET Material

A lightweight, abrasion-resistant, fire-retardant PVC-coated PET material ideal for rugged conditions.

Raw materials are not available for standalone purchase; instead, they are intended to be integrated into a tailor-made, custom-engineered solution. Explore the possibilities below or contact an engineer to start your custom application today!

Overview

- UL-rated meeting UL94 VTM-0

- Lightweight at only 0.014" thick

- Coated with fire-retardant PVC

The MLB jacketing is a lightweight, abrasion-resistant jacket made from a high-performance, fire-retardant material that is ideal for protecting cables in rugged conditions. This PVC-coated PET material combines durability with flexibility, making it perfectly suited for both indoor and outdoor cable protection.

Specifically engineered for use in harsh environments, the MLB material offers excellent protection against abrasion and mechanical stress, making it ideal for applications where long-lasting performance is critical. Whether for industrial cable bundling or other demanding settings, this abrasion-resistant jacket ensures cables are shielded from wear and tear.

With a thickness of 0.014 inches, this fire-retardant material provides robust insulation without adding unnecessary bulk. Its operational temperature range, from 5°F to 140°F (-15°C to 60°C), allows it to perform reliably in a wide range of environments.

Specifications

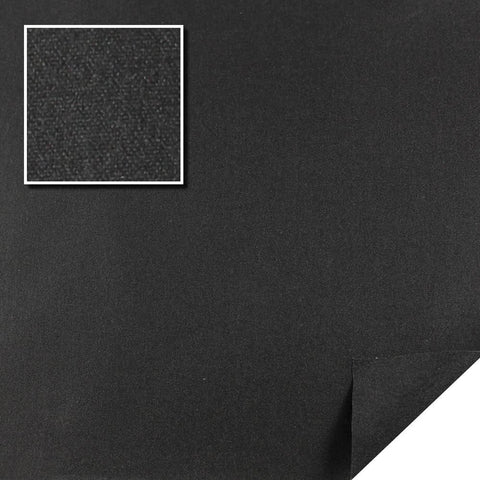

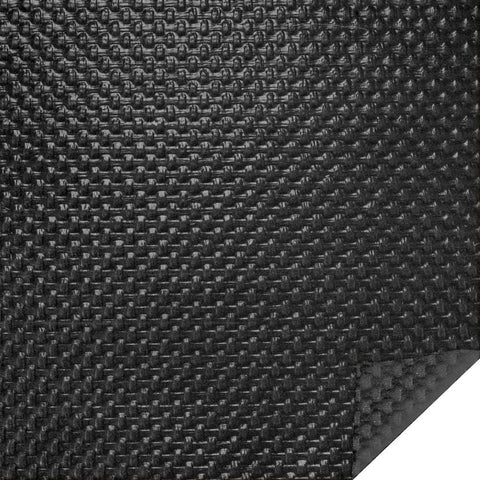

Similar Materials

|

|

|

|

| NAME | RPA-14 - POLYURETHANE COATED ARAMID FABRIC - 14 MIL | RPH-14 - POLYURETHANE COATED POLYESTER FABRIC - 14 MIL | FRC-15 CANVAS FABRIC - 15 MIL |

| DESCRIPTION | A Strong, Medium-Weight, Polyurethane Coated Aramid Fabric | A Flexible, Medium Weight, Polyurethane Coated Polyester Fabric, 14 mil | Lightweight Multi-Purpose Canvas Jacket, 15 Mil |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | Best | |

| Min Temperature | Low | Extreme | Moderate |

| Minimum Operating Temperature | -4°F | -67°F | -22°F |

| Max Temperature | Moderate | Moderate | Low |

| Maximum Operating Temperature | 302°F | 356°F | 140°F |

| Flexibility | Better | Better | |

| View | View | View |

MLB PVC-Coated PET Material

A lightweight, abrasion-resistant, fire-retardant PVC-coated PET material ideal for rugged conditions.

Material Sprcification: 1129

- UL-rated meeting UL94 VTM-0

- Lightweight at only 0.014" thick

- Coated with fire-retardant PVC

SPECIFICATIONS

DESCRIPTION

The MLB jacketing is a lightweight, abrasion-resistant jacket made from a high-performance, fire-retardant material that is ideal for protecting cables in rugged conditions. This PVC-coated PET material combines durability with flexibility, making it perfectly suited for both indoor and outdoor cable protection.

Specifically engineered for use in harsh environments, the MLB material offers excellent protection against abrasion and mechanical stress, making it ideal for applications where long-lasting performance is critical. Whether for industrial cable bundling or other demanding settings, this abrasion-resistant jacket ensures cables are shielded from wear and tear.

With a thickness of 0.014 inches, this fire-retardant material provides robust insulation without adding unnecessary bulk. Its operational temperature range, from 5°F to 140°F (-15°C to 60°C), allows it to perform reliably in a wide range of environments.