RPU-17 - Polyurethane Coated Polyester - 17 Mil

Reinforced Polyurethane Cable Jacket

Raw materials are not available for standalone purchase; instead, they are intended to be integrated into a tailor-made, custom-engineered solution. Explore the possibilities below or contact an engineer to start your custom application today!

Overview

- White in Color

- Environmentally Friendly (Non-PVC)

- Good Flexibility & High Tear Resistance

- Flame Retardant (NFPA-701 & FAR 25.853a)

- Multiple Closure Systems

- -40° To 71°C Operational Temperature Range

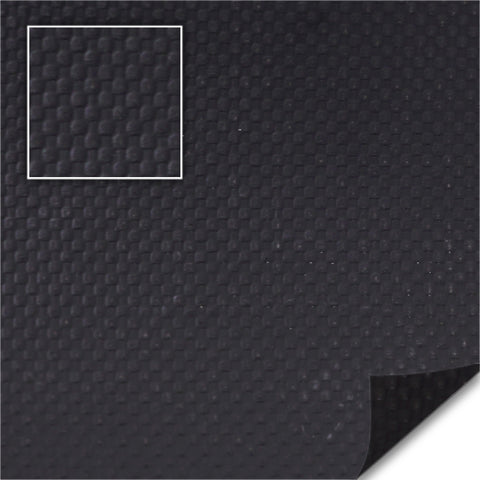

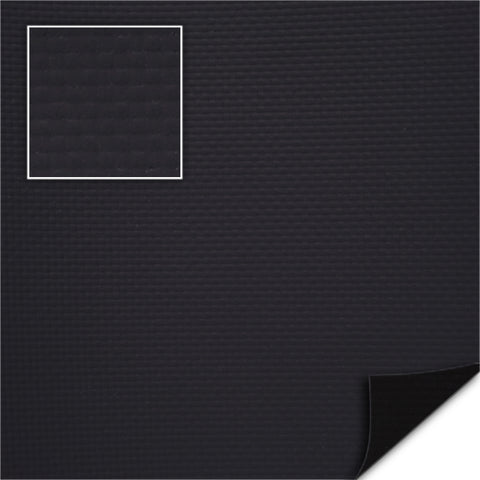

RPU-17 is a medium-weight, fire-retardant, poly(ether) urethane-coated polyester-fabric jacket material, engineered to provide a tough, flexible, and environmentally friendly alternative to PVC-based cable jackets. The durable polyester-fabric core offers exceptional tear resistance, making it ideal for demanding applications where reliability is critical. Its versatility allows it to be combined with a range of Zippertubing EMI Shielding materials, creating robust dual-purpose EMI-hardened jacket assemblies. Custom designs can also incorporate features such as mechanical zippers, hook and loop closures, stainless steel snap buttons, pressure-sensitive adhesives, and interlocking track closures to meet specific application needs.

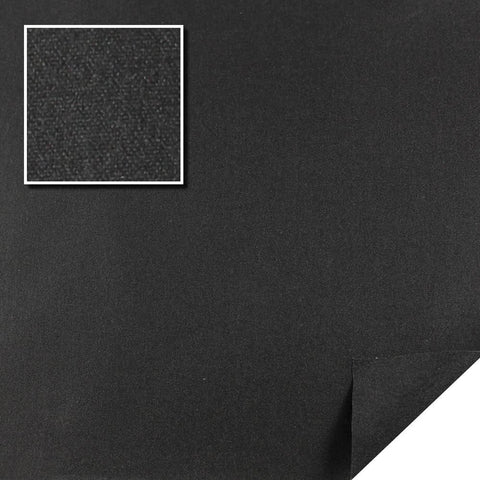

Polyurethane, as a non-PVC material, avoids the environmental and health risks associated with PVC, such as the release of harmful phthalates, plasticizers, and chlorine-based compounds over time. This makes RPU-17 an excellent choice for medical and cleanroom environments, where the use of toxic materials could lead to contamination, outgassing, and compromise strict hygiene standards.

The white color of the RPU-17 jacket not only enhances its suitability for medical and cleanroom settings but also contributes to maintaining cleanliness. The light-colored polyurethane material allows for easier detection of contaminants, enabling faster identification and removal of particles or stains. Additionally, its smooth surface facilitates easy cleaning and disinfection, ensuring compliance with the high hygiene requirements and low particulate counts essential in these environments.

Specifications

Similar Materials

|

|

|

|

| NAME | RPH-14 - POLYURETHANE COATED POLYESTER FABRIC - 14 MIL | RPA-14 - POLYURETHANE COATED ARAMID FABRIC - 14 MIL | FRC-15 CANVAS FABRIC - 15 MIL |

| DESCRIPTION | A Flexible, Medium Weight, Polyurethane Coated Polyester Fabric, 14 mil | A Strong, Medium-Weight, Polyurethane Coated Aramid Fabric | Lightweight Multi-Purpose Canvas Jacket, 15 Mil |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | Best | |

| Min Temperature | Extreme | Low | Moderate |

| Minimum Operating Temperature | -67°F | -4°F | -22°F |

| Max Temperature | Moderate | Moderate | Low |

| Maximum Operating Temperature | 356°F | 302°F | 140°F |

| Flexibility | Better | Better | |

| View | View | View |

RPU-17 - Polyurethane Coated Polyester - 17 Mil

Reinforced Polyurethane Cable Jacket

Material Sprcification: 1122

- White in Color

- Environmentally Friendly (Non-PVC)

- Good Flexibility & High Tear Resistance

- Flame Retardant (NFPA-701 & FAR 25.853a)

- Multiple Closure Systems

SPECIFICATIONS

DESCRIPTION

RPU-17 is a medium-weight, fire-retardant, poly(ether) urethane-coated polyester-fabric jacket material, engineered to provide a tough, flexible, and environmentally friendly alternative to PVC-based cable jackets. The durable polyester-fabric core offers exceptional tear resistance, making it ideal for demanding applications where reliability is critical. Its versatility allows it to be combined with a range of Zippertubing EMI Shielding materials, creating robust dual-purpose EMI-hardened jacket assemblies. Custom designs can also incorporate features such as mechanical zippers, hook and loop closures, stainless steel snap buttons, pressure-sensitive adhesives, and interlocking track closures to meet specific application needs.

Polyurethane, as a non-PVC material, avoids the environmental and health risks associated with PVC, such as the release of harmful phthalates, plasticizers, and chlorine-based compounds over time. This makes RPU-17 an excellent choice for medical and cleanroom environments, where the use of toxic materials could lead to contamination, outgassing, and compromise strict hygiene standards.

The white color of the RPU-17 jacket not only enhances its suitability for medical and cleanroom settings but also contributes to maintaining cleanliness. The light-colored polyurethane material allows for easier detection of contaminants, enabling faster identification and removal of particles or stains. Additionally, its smooth surface facilitates easy cleaning and disinfection, ensuring compliance with the high hygiene requirements and low particulate counts essential in these environments.