Overview

- Wrap-around heat shrink paired with water blocking adhesive provides superior protection for wires and cables

- Long-lasting and environmentally durable seal holds up against fluids, oils, greases, mild acids and alkalis

- Installation requires no disconnection or downtime

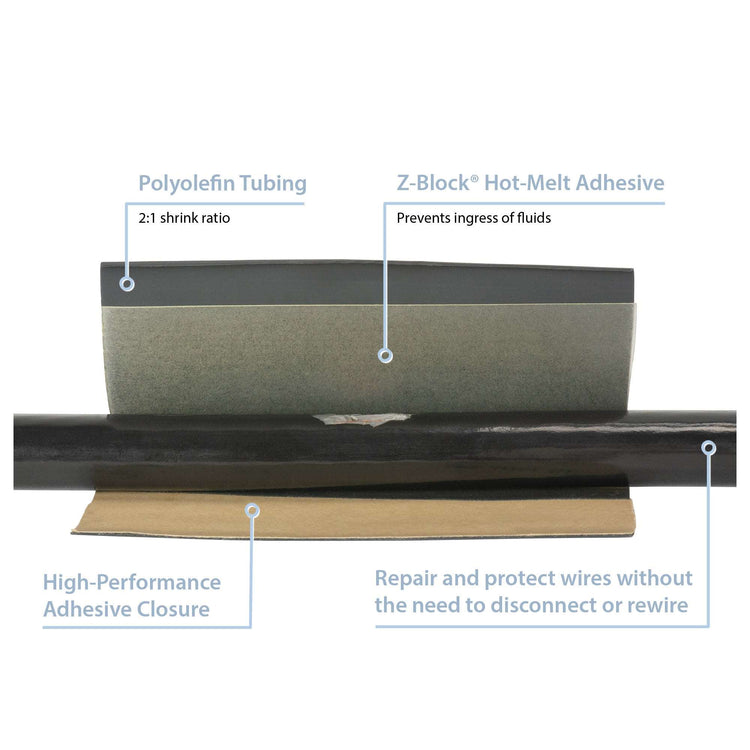

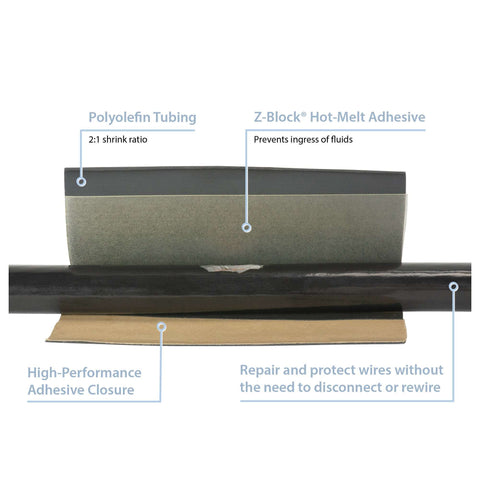

Shrink-N-Repair® (ES) is a water-blocking, flame-retardant, abrasion-resistant, chemical-resistant wrap-around 2:1 heat shrink that is RoHS compliant — ideal for protecting or repairing wires and cables against harsh environmental conditions. Combining our highly popular Shrink-N-Repair® product line with our Z-Block® water blocking adhesive is sure to provide a secure, environmental seal that will prevent fluids from damaging or penetrating components. Perfect for automotive applications including boat trailers, off-road vehicles, ATVs and more as Shrink-N-Repair® (ES) allows you to waterproof and seal wires from fluids, oils, greases, mild acids and alkalis as well as repair and re-jacket damaged, cracked or chafed components that cannot be disassembled.

Shrink-N-Repair® (ES) makes installation easy without disconnection or downtime due to its wrap-around design and adhesive with paper release liner — all you need is a heat gun and a standard pair of scissors. Shrink-N-Repair® (ES) is for wire or cable diameters up to 0.5”, and it can be cut to any desired length, offering versatility for many applications. The operational temperature range is 67°F to 275°F (-55°C to 100°C).

- Water blocking adhesive provides a secure, environmental seal

- No disconnection or re-wiring of components needed

- Operational temperature range of -67°F to 275°F (-55°C to 135°C)

- Resistant to most oils, fluids, mild acids, and alkalis

- Quick and easy installation with only a heat gun and a standard pair of scissors

- Can be cut to any desired length

Specifications

Overall Performance

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Water Blocking Type:

Polyolefin

- Mil-Spec:

- REACH:

- Dielectric Strength:

- Elongation:

- Flammability:

- Fungicide:

- Longitudinal Shrinkage:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

- Specific Gravity:

- Outgasssing (%TML):

- Outgassing (%CVCM):

- Outgassing (%WVR):

Tape (Specialty Surface)

Polyamide Hot Melt (100)

- REACH:

- Abrasion Resistance:

- Elongation:

- Flexibility:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Water Absorption:

- RoHS:

- Shelf Life:

- Softening Temp:

- Softening Temp Variance:

Similar products

|

|

|

|

| NAME | PRT® MIL-SPEC WRAP-AROUND HEAT SHRINK TUBING | SHRINK-N-REPAIR® (M) WRAP-AROUND HEAT SHRINK | PRT® (ES-135) WATER-BLOCKING WRAP-AROUND HEAT SHRINK |

| DESCRIPTION | A wrap-around heat shrink made from MIL-SPEC tubing that repairs electrical systems and assembled components and is resistant to abrasion and chemicals. | A wrap-around, abrasion-resistant, fluid-resistant heat shrink that repairs wires or cables with diameters up to 0.5”. | A wrap-around, military-grade heat shrink paired with a high-temperature water blocking, hot-melt adhesive that protects against harsh environmental conditions. |

| Closure | Tape (Specialty Surface) | Tape (Specialty Surface) | Tape (Specialty Surface) |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Wire Repair | Wire Repair | Water Blocking |

| Min Temperature | Extreme | Moderate | Extreme |

| Minimum Operating Temperature | -67°F | -67°F | -67°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 275°F | 275°F | 275°F |

| Flexibility | |||

| View | View | View |

Guides

Shrink-N-Repair® (ES) Tubing with Water Blocking

A wrap-around heat shrink paired with water blocking adhesive for repairing wires or cable diameters up to 0.5".

Drawing Number(s): ZT20-04-009

Selected Part Number: ZT20-04-009-B-X12.0

Features

Benefits

Shrink-N-Repair® (ES) Tubing with Water Blocking

Shrink-N-Repair® (ES) Tubing with Water Blocking

MATERIAL SPECIFICATIONS