Overview

- EMI shielding fabric provides better protection from electromagnetic interference

- Viton® heat shrink meets MIL-DTL-23053/13 and MIL-R-46846, Type III, Class 1

- Heat-shrink tubing provides the best resistance to abrasion and offers the best flexibility

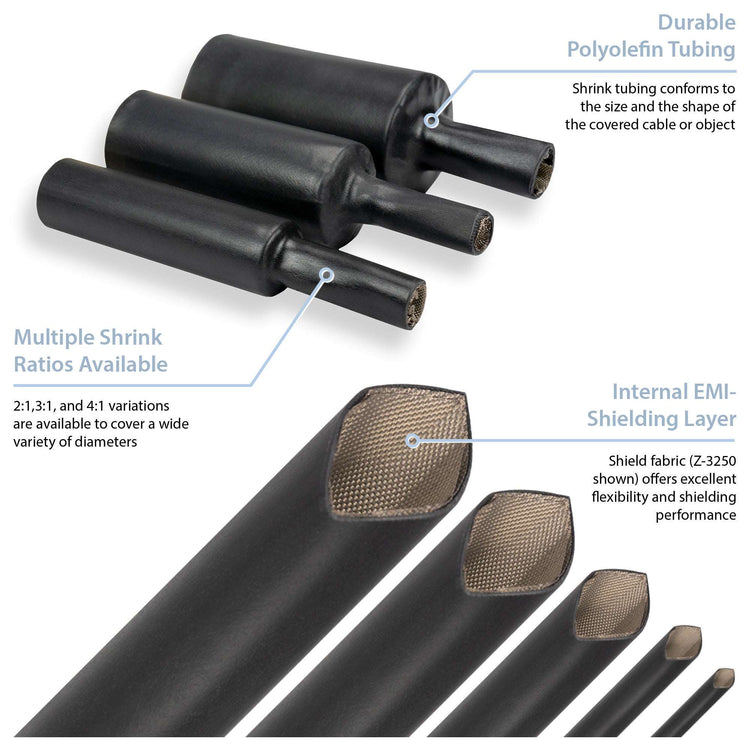

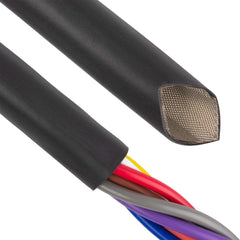

Shrink-N-Shield® (FE) combines two proven technologies into a single, easy to install product for adding EMI shield protection to wire and cable bundles with diameters of 1.0" and less. Makes adding an EMI shield or secondary EMI shielding to wire and cable a snap. The product is comprised of SAE-AMS-DTL-23053/13 flexible Fluoroelastomer heat shrink tubing and Zippertubing's Z-3250 conductive cloth which has outstanding shielding properties. The outer tubing is a high temperature, rubber-like jacket which is highly fluid resistant and flame retardant. The operational temperature of this composite product is 175°C, but it can withstand short spikes to 200°C. This product is supplied in four foot long sticks.

- High-temperature heat shrink can withstand moderately high temperatures

- Shields from EMI, RFI, and EMF

- Operational temperature range of -67°F to 302°F (-55°C to 150°C)

- Heat-shrink tubing protects from the toughest of conditions and environments

- Z-3250 shielding fabric has a nickel coating for excellent corrosion resistance

- Installation only requires a standard heat gun

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter - Before Shrink:

- Material:

- Heat Shrink Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shield Bonding:

- Shielding:

- Shielding Material:

- Shrink Ratio:

Viton

- REACH:

- Copper Corrosion:

- Dielectric Volts/Mil:

- Elongation:

- Flammability:

- Longitudinal Shrinkage:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Water Absorption:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

Z-3250

Similar products

|

|

|

|

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | PRT® (1553-135) WATER-BLOCKING WRAP-AROUND HEAT SHRINK | SHRINK-N-SHIELD® (3:1) EMI SHIELDED HEAT SHRINK TUBING |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A wrap-around, MIL-SPEC heat shrink paired with a high-temperature, water-blocking adhesive that comes equipped with the Z-3250-Tape™ for shielding against EMI. | A heat-shrink tubing that provides exceptional shielding from EMI, RFI and EMF. |

| Closure | Tape (Specialty Surface) | ||

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Pull-Through | Wrap-Around | Pull-Through |

| Purpose | EMI Shielding | Water Blocking | Small Diameters |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -67°F | -67°F | -67°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 275°F | 275°F | 275°F |

| Flexibility | |||

| View | View | View |

Guides

Shrink-N-Shield® (FE) Fluoroelastomer Shielded Tubing

A military-grade Viton® heat-shrink tubing paired with the Z-3250-CN shielding fabric to protect from EMI. 2:1 shrink ratio.

Drawing Number(s): ZT03-18-003

Selected Part Number: ZT03-18-003-0.1875-B-X48.0

Features

Benefits

Shrink-N-Shield® (FE) Fluoroelastomer Shielded Tubing

SHIELDING EFFECTIVENESS - Z-3250

Shrink-N-Shield® (FE) Fluoroelastomer Shielded Tubing

MATERIAL SPECIFICATIONS