Overview

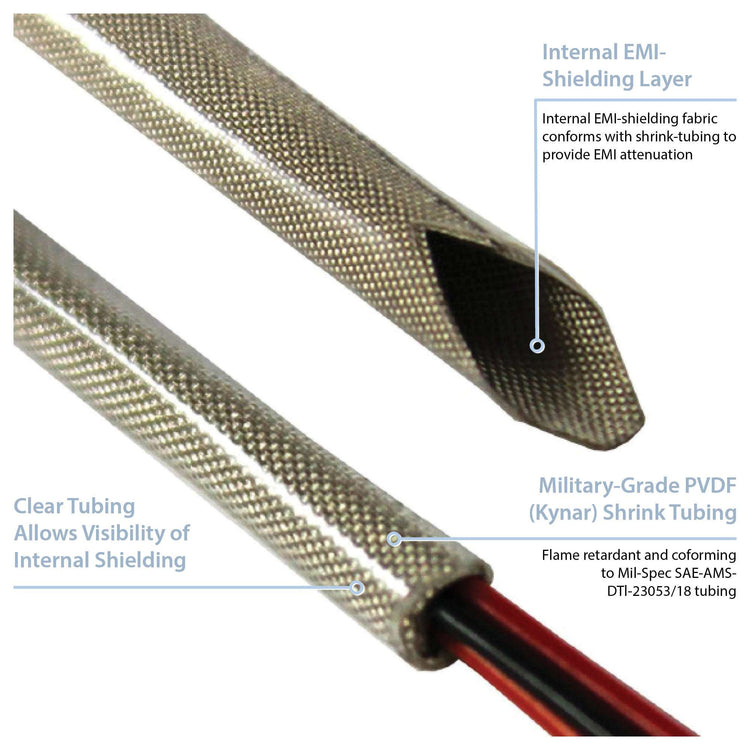

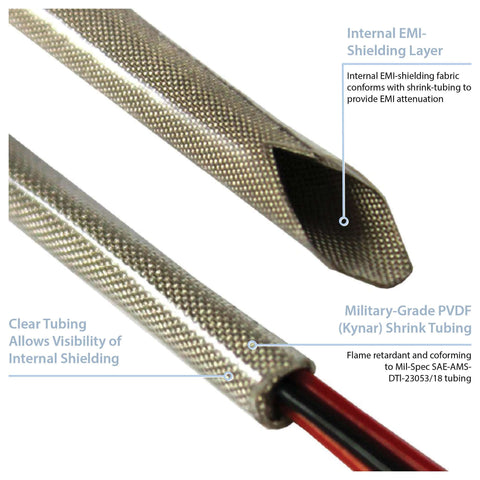

- EMI shielding fabric provides better protection from electromagnetic interference

- Kynar® heat shrink meets MIL-DTL-23053/18, Class 3 and UL224, VW-1

- Heat-shrink tubing provides best resistance to abrasion and fluid

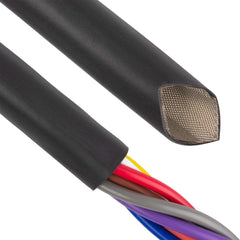

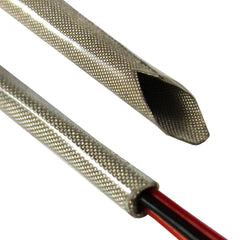

Shrink-N-Shield® (PVDF) combines two proven technologies into a single, easy to install product for adding EMI shield protection to wire and cable bundles with diameters of 1/2" and less. Makes adding an EMI shield or secondary EMI shielding to wire and cable a snap. The product is comprised of a flexible, fire retardant, Polyvinylidene Fluoride tubing and Zippertubing's Z-3250 conductive cloth with outstanding shielding properties. The PVDF polymer jacket is a commercial variant of SAE-AMS-DTL-23053/18 tubing and the special formulation makes it more flexible than standard Mil-Spec tubing while still offering outstanding abrasion resistance. The product has an operational temperature range of -55°C to 150°C. This product is supplied in four foot long sticks.

- Military-grade and UL-rated Kynar® heat-shrink

- Shields from EMI, RFI, and EMF

- Operational temperature range of -67°F to 221°F (-55°C to 105°C)

- Flame-retardant, abrasion-resistant, fluid-resistant tubing

- Z-3250 shielding fabric has a nickel coating for excellent corrosion resistance

- Installation only requires a standard heat gun

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter - Before Shrink:

- Material:

- Heat Shrink Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

- Shrink Ratio:

Kynar

- REACH:

- Chemical Resistance:

- Copper Corrosion:

- Dielectric Volts/Mil:

- Elongation:

- Flammability:

- Longitudinal Shrinkage:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Water Absorption:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

Z-3250

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Guides

Shrink-N-Shield® (PVDF) EMI Shielded Heat Shrink Tubing

A Kynar® heat-shrink tubing that is MIL-SPEC and UL-rated paired with Z-3250 shielding fabric to protect from EMI.

Drawing Number(s): ZT02-18-001

Selected Part Number: ZT02-18-001-0.1875-C-X48.0

Features

Benefits

Shrink-N-Shield® (PVDF) EMI Shielded Heat Shrink Tubing

SHIELDING EFFECTIVENESS - Z-3250

Shrink-N-Shield® (PVDF) EMI Shielded Heat Shrink Tubing

MATERIAL SPECIFICATIONS