Overview

- Thin wall polyolefin is ideal for applications where space and weight is limited

- UL-rated meeting UL 224, VW-1

- Combines EMI shielding with heat shrink tubing for an all-in-one solution

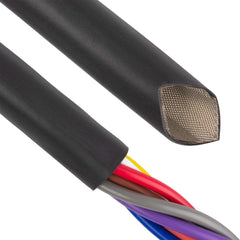

Shrink-N-Shield® (TW) is an EMI shielding solution that features thin wall polyolefin heat shrink tubing and the Z-3250 shielding cloth. The thin wall polyolefin is lightweight and flexible, making this tubing ideal for applications that are limited with space and weight. The heat shrink is UL-rated for flame retardancy, meeting UL 224, VW-1, and has a 2:1 shrink ratio allowing for versatility in applications.

The Z-3250 shielding cloth is made of a taffeta fabric plated with copper then nickel for excellent corrosion resistance. The EMI shielding cloth will not flake or deteriorate over time, so you can be confident your wires or cables will have long-lasting protection from EMI, RFI, and EMF.

Shrink-N-Shield® (TW) is offered for diameters ranging from 0.875” to 1.25” and comes in 4-foot sticks, with custom sizes and lengths available upon request. The operational temperature range is -67°F to 257°F (-55°C to 125°C).

- Flame retardant per UL 224, VW-1

- Provides complete protection from EMI, RFI, and EMF

- Operational temperature range is -67°F to 257°F (-55°C to 125°C)

- Flexible and lightweight heat shrink tubing

- Ideal for grouped wires or a tight fit

- Shrink ratio of 2:1

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter - Before Shrink:

- Material:

- Heat Shrink Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shield Bonding:

- Shielding:

- Shielding Material:

- Shrink Ratio:

Thin Wall Polyolefin

- REACH:

- Dielectric Strength:

- Elongation:

- Flammability:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

- Specific Gravity:

Z-3250

Similar products

|

|

|

|

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | PRT® (1553-135) WATER-BLOCKING WRAP-AROUND HEAT SHRINK | SHRINK-N-SHIELD® (3:1) EMI SHIELDED HEAT SHRINK TUBING |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A wrap-around, MIL-SPEC heat shrink paired with a high-temperature, water-blocking adhesive that comes equipped with the Z-3250-Tape™ for shielding against EMI. | A heat-shrink tubing that provides exceptional shielding from EMI, RFI and EMF. |

| Closure | Tape (Specialty Surface) | ||

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Pull-Through | Wrap-Around | Pull-Through |

| Purpose | EMI Shielding | Water Blocking | Small Diameters |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -67°F | -67°F | -67°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 275°F | 275°F | 275°F |

| Flexibility | |||

| View | View | View |

Guides

Shrink-N-Shield® (TW) Flexible EMI Shielded Tubing

A flexible, flame-retardant, thin wall polyolefin heat shrink and EMI shielding solution that features a 2:1 shrink ratio and the Z-3250-CN shielding cloth.

Drawing Number(s): ZT02-18-003

Selected Part Number: ZT02-18-003-0.1875-B-X48.0

Features

Benefits

Shrink-N-Shield® (TW) Flexible EMI Shielded Tubing

SHIELDING EFFECTIVENESS - Z-3250

Shrink-N-Shield® (TW) Flexible EMI Shielded Tubing

MATERIAL SPECIFICATIONS