Overview

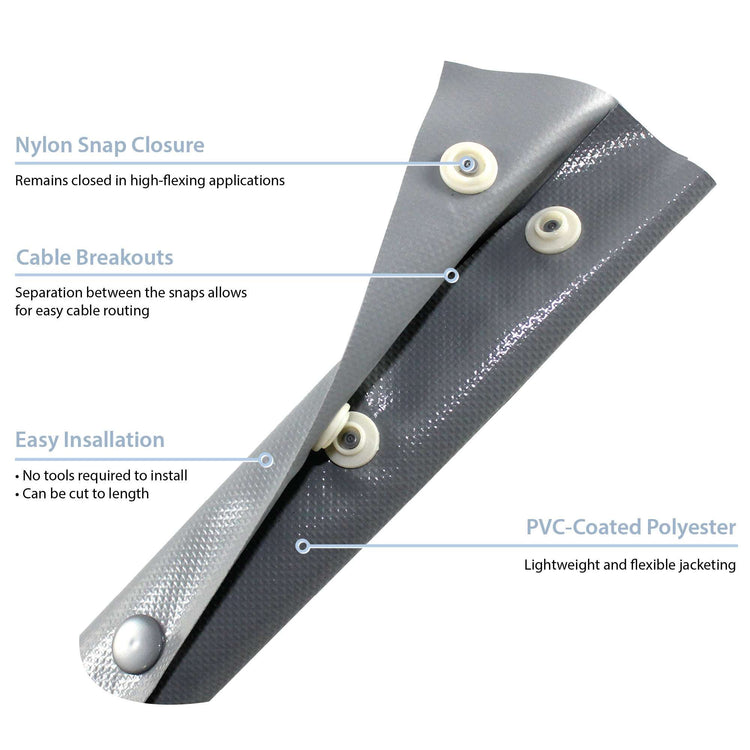

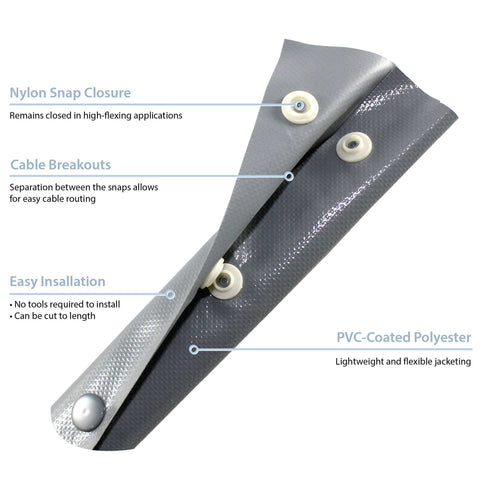

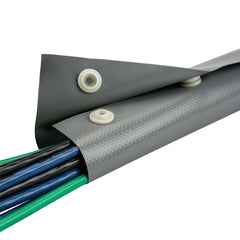

- Easy to install snap-button closure that requires no tools and can be cut to length

- Good abrasion properties with excellent flexibility

- An economical flame retardant cable bundling solution that offers breakouts for multiple wires

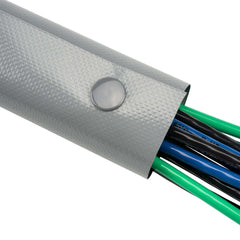

Snap-Grip® is completely customizable polyester, PVC-coated cable management solution equipped with nylon snap buttons. The jacketing is a lightweight, abrasion-resistant material that is strong enough to withstand high flexing conditions. Snap-Grip® is available in six colors, as well as a clear option. If your applications may require color coding to indicate certain precautions, or if you are simply looking for a more colorful way to bundle wires or cables, these options are a great choice. The nylon snap buttons enable quick application. Snap-Grip® requires no tools, allowing for fast, clean installation. Because of the spacing between snaps, you can easily cut to any length required.

Snap-Grip® is ideal for a variety of applications and environments. From an office to a server room, Snap-Grip® can be quickly and easily assembled while still supporting breakouts and access to the components inside. Snap-Grip® organizes and bundles while also protecting from abrasion. Keep in mind, a Snap-Grip® product can be made from any our jacketing materials to fit your specific requirements.

Snap-Grip® is available for diameters ranging from 0.375” to 4”, with custom sizes and lengths available upon request, and it has an operational temperature range of -40°F to 179°F (-40°C to 92°C).

If your application requires EMI shielding, we offer Snap-Grip® (Al), or if the application requires heat shielding, we also offer Snap-Grip® (SAM-1000).

- Easy to secure and re-enter as needed

- No tools required for installation

- Operational temperature range of -40°F to 179°F (-40°C to 92°C)

- Flexible for high-flexing conditions

- Range of colors available, as well as clear

- Custom sizes and diameters available

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Dielectric Constant:

- Elongation:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Tensile Strength:

PVC-coated PET

- Base Fabric:

- Surface Resistivity:

- Coating:

- Dielectric Volts/Mil:

- Elongation:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tensile Strength:

Nylon Snaps

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Snap-Grip® Cable Bundling

A lightweight, PVC-coated cable bundling and protection solution that is available in a range of colors and is equipped with nylon snaps for easy re-entry.

Drawing Number(s): ZT21-08-002

Selected Part Number: ZT21-08-002-0.375-G-X300.0

Features

Benefits

Snap-Grip® Cable Bundling

Snap-Grip® Cable Bundling

MATERIAL SPECIFICATIONS