Overview

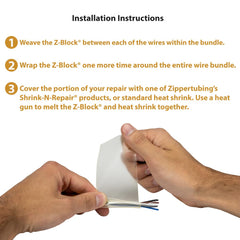

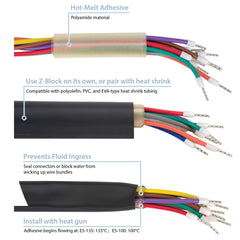

- Easy to install with simply melting down with a heat gun

- Lightweight and an environmental sealant for any shape application

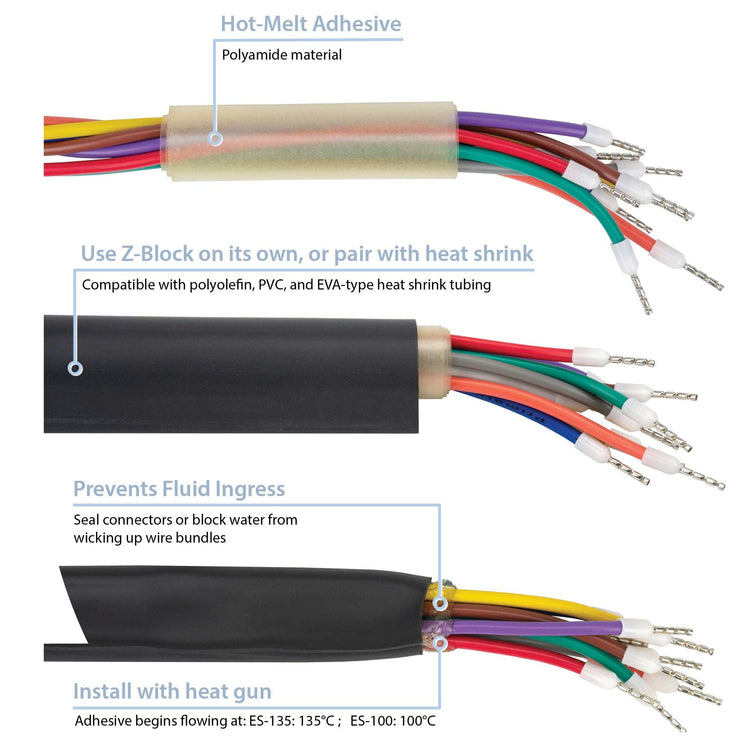

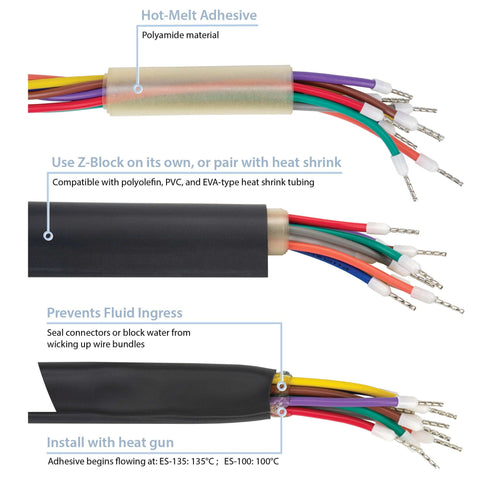

- Compatible with polyolefin, PVC, and EVA-type heat shrink tubing

Z-Block® is resistant to most fluids, making this hot-melt, heat shrink tape the ideal solution for protecting wires or cables that may be exposed to environments with water, oils, or greases. Z-Block® will create no corrosion of copper and aluminum metal substrates, and is RoHS compliant. Z-Block® is an environmental seal that will prevent any fluid from damaging or penetrating wires or cables, and is versatile enough to be used on various applications.

Z-Block® pairs perfectly with our Shrink-N-Repair® to seal and repair wires from damage, or to prevent damage from occurring. Wrapping your wires or cables with Shrink-N-Repair®, and sealing with Z-Block® creates an impossible barrier for fluids to enter, which extends the lives of your components and ensures ultimate protection.

Z-Block® is available in two different temperature ranges – Z-Block® (100) can be used on applications exposed to temperatures up to 212°F (100°C), and Z-Block® (135) can be exposed to temperatures up to 275°F (135°C).

- Corrosion resistant for copper and aluminum metal substrates

- Operational temperature range of -67°F to 212°F (-55°C to 100°C)

- Resistant against various oils such as brake fluid, engine coolant, ASTM reference oil #3, and automatic transmission fluid, making Z-Block® ideal for the automotive industry

- Can be intertwined easily between wire bundles to protect each wire completely

Specifications

Overall Performance

- Closure:

- Material:

- Flame Retardant:

- Heat Shrink Material:

- Material:

- Thickness:

- Material Type:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Width:

Polyamide Hot Melt (100)

- REACH:

- Elongation:

- Material:

- Color:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Water Absorption:

- RoHS:

- Shelf Life:

- Softening Temp:

- Softening Temp Variance:

Similar products

|

|

|

|

| NAME | PRT® MIL-SPEC WRAP-AROUND HEAT SHRINK TUBING | SHRINK-N-REPAIR® (M) WRAP-AROUND HEAT SHRINK | PRT® (ES-135) WATER-BLOCKING WRAP-AROUND HEAT SHRINK |

| DESCRIPTION | A wrap-around heat shrink made from MIL-SPEC tubing that repairs electrical systems and assembled components and is resistant to abrasion and chemicals. | A wrap-around, abrasion-resistant, fluid-resistant heat shrink that repairs wires or cables with diameters up to 0.5”. | A wrap-around, military-grade heat shrink paired with a high-temperature water blocking, hot-melt adhesive that protects against harsh environmental conditions. |

| Closure | Tape (Specialty Surface) | Tape (Specialty Surface) | Tape (Specialty Surface) |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Wire Repair | Wire Repair | Water Blocking |

| Min Temperature | Extreme | Moderate | Extreme |

| Minimum Operating Temperature | -67°F | -67°F | -67°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 275°F | 275°F | 275°F |

| Flexibility | |||

| View | View | View |

Z-Block® (100) Water Blocking Hot-Melt Adhesive Tape

A hot-melt adhesive tape that blocks and seals wires from water, oils, greases, and most fluids and can handle temperatures up to 212°F (100°C).

Drawing Number(s): ZT02-03-002

Selected Part Number: ZT02-03-002-2.0-X300.0

Features

Benefits

Z-Block® (100) Water Blocking Hot-Melt Adhesive Tape

Z-Block® (100) Water Blocking Hot-Melt Adhesive Tape

MATERIAL SPECIFICATIONS