Overview

- Lightweight and flexible jacketing

- Resistant to abrasion, fluid and fungus

- Acrylic adhesive closure provides secure seal

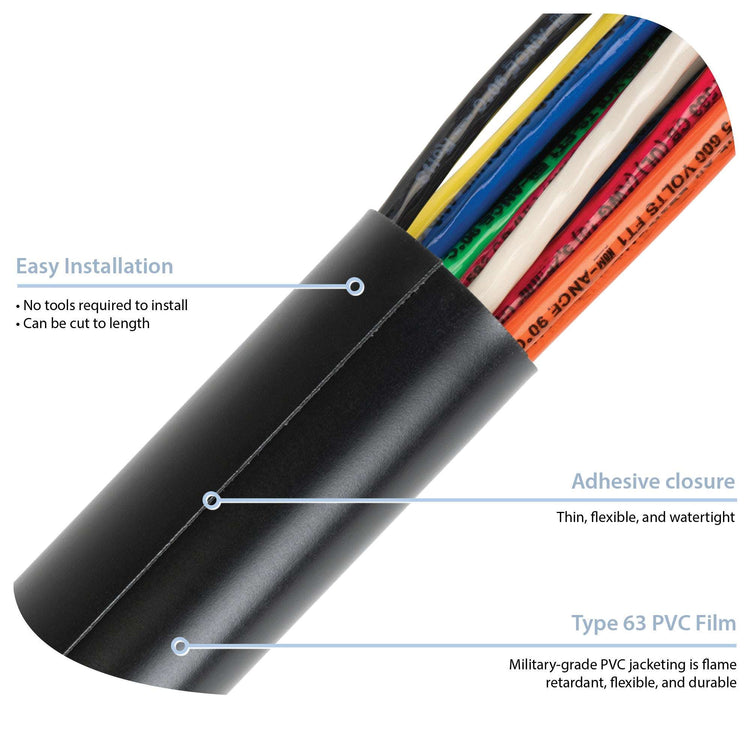

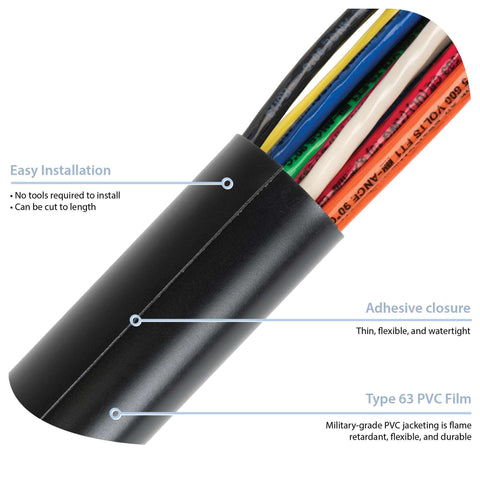

Z-Wrap® (63) provides secure and long-lasting component protection. The jacketing is a calendared, virgin PVC film that is abrasion resistant, fluid resistant, fungus resistant, and flame retardant. The jacketing is available in two thicknesses: 0.01” (63-10) or 0.02” (63-20). The 63-10 would be the ideal choice for applications needing a bit lighter weight and flexibility, while the 63-20 would be ideal for applications that may experience a bit more rugged of conditions. The jacketing material meets specification MIL-I-631D, Type F, Form S, as well as MIL-I-631, Grade C, Class I, Category 1. The 63 jacketing is also resistant to copper corrosion, and has a 600-volt dielectric rating. The acrylic-based transfer adhesive has a high-strength bond, creates a secure seal and is equipped with a paper release liner for clean application. The adhesive is also fire retardant and RoHS compliant.

Z-Wrap® (63) can be installed quickly and save time and resources without the worry of disassembly. Z-Wrap® (63) requires no tools for installation – just wrap around the wire or cable bundle, remove paper release liner from adhesive strip, and seal securely. Z-Wrap® (63) can also be easily cut to any desired length with a pair of standard scissors.

Z-Wrap® (63) is offered in diameters ranging from 0.375” to 4”, with custom sizes available upon request. Z-Wrap® (63) has an operational temperature range of -4°F to 160°F (-20°C to 74°C).

- Abrasion resistant, fluid resistant, fungus resistant and flame retardant

- Can be cut to length if needed

- Operational temperature range of -4°F to 200°F (-20°C to 105°C)

- Military-grade jacketing makes this solution ideal for rugged conditions

- Adhesive closure provides permanent seal

- Quick installation – wrap, release paper liner, and seal adhesive closed

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Copper Corrosion:

- Dielectric Constant:

- Dielectric Strength:

- Material:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Tensile Strength:

Tape (Plasticizer Resistant)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Z-Wrap® (63) Cable Bundling

A wrap-around cable bundling and protection solution that is military-grade, abrasion-resistant, fluid-resistant, and flame-retardant with an adhesive closure.

Drawing Number(s): ZT00-04-007, ZT97-04-020

Selected Part Number: ZT00-04-007-0.375

Features

Benefits

Z-Wrap® (63) Cable Bundling

Overall Performance

- Diameter:

- Closure:

- Copper Corrosion:

- Dielectric Constant:

- Dielectric Strength:

- Material:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Tensile Strength:

Z-Wrap® (63) Cable Bundling