Overview

- Jacketing meets Mil-C-27072, Mil-C-13777, Mil-I-3930/21, and Mil-Std-810, as well as UL94 V-0

- Complete 360-degree protection that can be cut to length for a variety of application uses

- Adhesive is equipped with a paper release liner for quick and easy installation

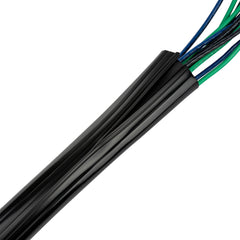

Z-Wrap® (PFR) combines the strength of the PFR jacketing with a long-lasting, permanent adhesive closure. The PFR material is a polyurethane film that is flexible and available in two thicknesses; PFR-10 is more lightweight at only 0.01” thick and provides better abrasion resistance, while the PFR-18 is 0.018” thick and offers the best in abrasion resistance. The military-grade jacketing meets Mil-C-27072, Mil-C-13777, Mil-I-3930/21, as well as Mil-Std-810 The jacketing is tough with having resistance to flames, chemicals, abrasion, fluids, fungus, and ozone. The acrylic adhesive closure is solvent resistant, fire retardant, and can handle high temperatures.

Installing Z-Wrap® (PFR) requires no additional tools; just peel off the paper release liner and seal the product around your components. Z-Wrap® (PFR) can also be cut with a standard pair of scissors for applications that may have varying lengths of wires and cables.

Z-Wrap® (PFR) is offered for diameters ranging from 0.375” to 4”, with custom sizes available upon request. The operational temperature range is -40°F to 225°F (-40°C to 107°C).

- Resistant to abrasion, fluids, chemicals, fungus, and ozone

- Provides complete 360-degree protection

- Operational temperature range is -40°F to 225°F (-40°C to 107°C)

- No additional tools required for installation

- Military-grade jacketing ideal for aerospace and military applications

- High-bond strength adhesive for lasting seal

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Copper Corrosion:

- Dielectric Constant:

- Dielectric Strength:

- Elongation:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tensile Strength:

PFR-10

- Copper Corrosion:

- Dielectric Volts/Mil:

- Dielectric Strength:

- Elongation:

- Flammability:

- Durometer:

- Fungus Resistance:

- Color:

- Thickness:

- Thickness Variance:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tensile Strength:

- Ozone Resistance:

- Specific Gravity:

PFR-18

- Mil-Spec:

- Copper Corrosion:

- Dielectric Constant:

- Dielectric Strength:

- Elongation:

- Flame Retardant:

- Fungus Resistance:

- Color:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

- Ozone Resistance:

Tape (Plasticizer Resistant)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Z-Wrap® (PFR) Polyurethane Cable Bundling

A military-grade, wrap-around cable bundling solution utilizing a flame-retardant, chemical, fluid, and abrasion-resistant jacketing paired with an adhesive.

Drawing Number(s): ZT18-04-002, ZT97-04-028

Selected Part Number: ZT18-04-002-0.375

Features

Benefits

Z-Wrap® (PFR) Polyurethane Cable Bundling

Z-Wrap® (PFR) Polyurethane Cable Bundling

MATERIAL SPECIFICATIONS