Overview

- Fire-retardant, polyurethane-coated polyester jacketing

- Acrylic adhesive is solvent, humidity, and U.V. resistant

- Wrap-around product requires no tools for installation – just remove liner and seal closed

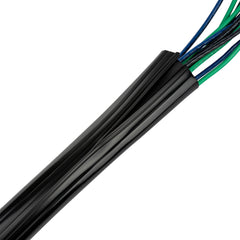

Z-Wrap® (RPU) is a permanent, wrap-around cable bundling and protection solution that utilizes our RPU-17 jacketing paired with a high-strength adhesive. The RPU-17 jacketing is made of a flexible, white reinforced polyurethane that is resistant to many fluids, chemicals, and oils, as well as being best in resistance to abrasion. The jacketing is also fire retardant, offers decent flexibility, and contains no PVC material. The fiber-reinforced acrylic adhesive generates a strong bond and a secure seal. The adhesive has excellent resistance to solvent, humidity, and U.V. The adhesive also has a paper release liner allowing for a quick and clean application.

The installation of Z-Wrap® (RPU) can be accomplished quickly, saving time and resources without the hassle of disassembly. Z-Wrap® (RPU) requires no tools for installation; just wrap around the wire or cable, remove the paper release liner from the adhesive strip, and seal. Z-Wrap® (RPU) can also be cut to any desired length with a pair of standard scissors.

Z-Wrap® (RPU) is offered in diameters ranging from 0.375” to 8”, with custom sizes available upon request. The operational temperature range is -40°F to 160°F (-40°C to 71°C).

* Z-Wrap® (RPU) is not manufactured using a clean room in sterile conditions, but with the right procedures, it could be used in the medical field, including in hospitals, operating rooms, trauma centers, and emergency rooms.

- Jacketing does not contain any PVC material

- Can be cut to any desired length

- Operational temperature range is -40°F to 160°F (-40°C to 71°C)

- No tools are required for installation

- RPU-17 jacketing is resistant to fluids and abrasion

- Perfect cable bundling for clean room applications

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

RPU-17

- Solvent Resistance:

- REACH:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Tape (Plasticizer Resistant)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Z-Wrap® (RPU) Cable Bundling

A white, PVC-free, wrap-around cable bundling solution utilizing an adhesive closure, making this solution ideal for medical and clean room applications.

Drawing Number(s): ZT16-04-005

Selected Part Number: ZT16-04-005-0.375-W

Features

Benefits

Z-Wrap® (RPU) Cable Bundling

Z-Wrap® (RPU) Cable Bundling

MATERIAL SPECIFICATIONS