Overview

- PVL-10 jacketing is military grade with meeting MIL-C-43006G, Type II, Class 1

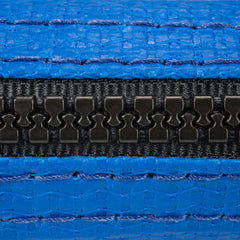

- Nylon zipper closure allows for re-entry to components as needed

- Jacketing, zipper, and thread are available in a wide range of colors for a completely custom solution

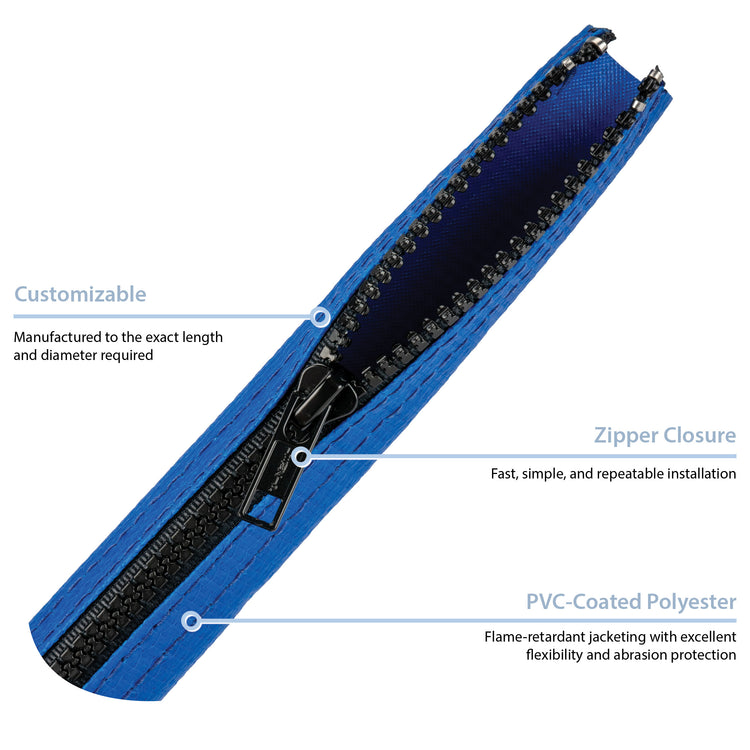

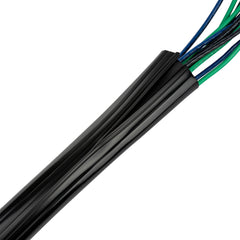

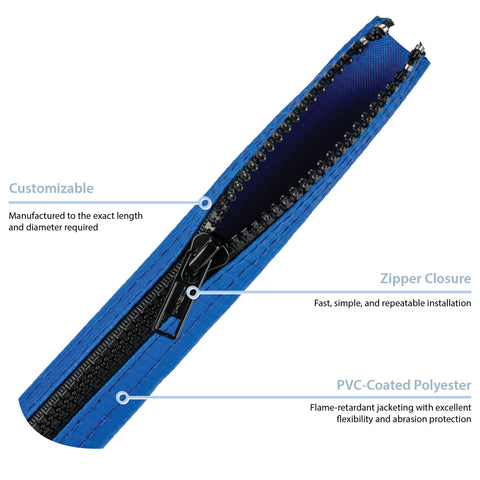

Professionally bundle your messy wires or cables. Zip-Wrap® (PVL) is a lightweight, abrasion-resistant, zipper sleeve comprised of flame-retardant polyester fabric that is coated with Polyvinyl Chloride (PVC) on both sides.

This product is versatile and well suited for any round, flat, or rectangular cable bundling application. You now have the ability to quickly wrap, zip, and enjoy.

This product is comprised of a molded Nylon tooth plastic zipper, PVL-10 coated fabric material and is sewn using a nylon thread. The zipper style of closure allows for a seamless installation without the need for tooling on assemblies that require re-entry after your installation.

Zip-Wrap® is ideal for cable bundles, wire harnesses, hoses and other applications where flexibility, strength, chemical resistance and abrasion protection is needed. Custom colors, lengths, widths, closure options as well as jacketing materials are also available.

- Wide range of color combinations for color-coded bundling

- Easy installation, no tools required

- Operational temperature range of -40°F to 180°F (-40°C to 82°C)

- Jacketing offers better resistance to abrasion for use in rugged conditions

- Zipper closure allows for installation in the production environment without disconnection of wires or cables

- Lightweight and flexible for flexing components

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Zipper Color:

PVL-10

- Mil-Spec:

- REACH:

- Chemical Resistance:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Zipper (Nylon)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Zip-Wrap® (PVL) Flexible Cable Bundling

A lightweight, abrasion-resistant jacketing with a zipper offered in many color combinations for protective, color-coded cable bundling.

Drawing Number(s): ZT98-07-011

Selected Part Number: ZT98-07-011-0.5-B-B

Features

Benefits

Zip-Wrap® (PVL) Flexible Cable Bundling

Zip-Wrap® (PVL) Flexible Cable Bundling

MATERIAL SPECIFICATIONS