Overview

- RPA-14 is an Aramid fabric coated with polyurethane that provides durable protection from abrasion and wear

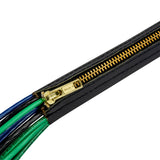

- Brass zipper is sewn to jacketing with Kevlar thread for long-lasting bond between materials

- Wrap-around solution allows for installation without disconnection or re-wiring of components

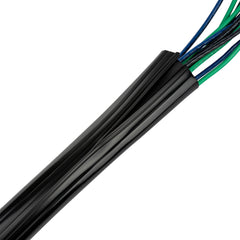

Zip-Wrap® (RPA) is a strong, pliable, medium weight, complete 360° abrasion protection solution for wires, cables, hoses, and other components. This product is perfect for harsh environments with various temperatures ranging from -4°F to 302°F. Zip-Wrap® (RPA) can be customized to fit virtually any length and size, allowing for easy installation with a zipper closure system.

Zip-Wrap® (RPA) is comprised of a polyurethane-coated aramid outer jacketing material (RPA-14), and a high-temperature brass zipper closure that allows for a seamless installation and re-entry. The RPA-14 material is a medium weight, pliant polyurethane coated polyester fabric, which is resistant to wear, abrasives, and extreme temperatures. The materials are sewn together using one of the highest-heat rated threads we offer, an aramid Kevlar thread. This product is engineered to protect your most valuable components against abrasion and varying temperatures, as a durable, economical cable management solution.

- Jacketing is PVC-free for applications with such restrictions

- No re-wiring or disassembly of components needed for installation

- Operational temperature range of -4°F to 302°F (-20°C to 150°C)

- Provides 360-degree protection and bundling of components

- Offers the best abrasion resistance for use in rugged conditions

- No tools are required for installation

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

RPA-14

- Weight:

- Base Fabric:

- Coating:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tear Strength:

Toothed Zipper (High-Temp Brass)

Kevlar Thread

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Zip-Wrap® (RPA) High Temperature Cable Bundling

A wrap-around cable management solution that pairs an abrasion-resistant, PVC-free jacketing with a brass zipper closure for quick and easy installation.

Drawing Number(s): ZT18-07-010

Selected Part Number: ZT18-07-010-0.5

Features

Benefits

Zip-Wrap® (RPA) High Temperature Cable Bundling

Zip-Wrap® (RPA) High Temperature Cable Bundling

MATERIAL SPECIFICATIONS