Overview

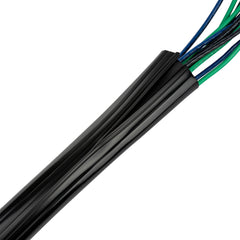

- Perfect for cable bundles, wire harnesses, hoses, and other components in which flexibility, strength, and low to high temperatures are experienced

- Ideal for applications that may require re-entry

- Great for harsh environments where wear resistance and abrasion protection are essential

The perfect component protection solution for high-heat or extremely cold environments!

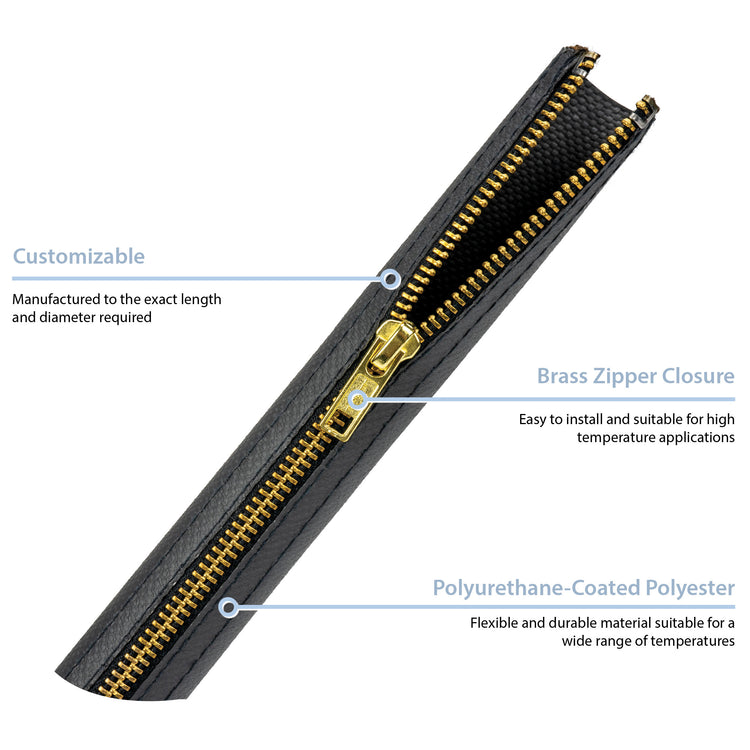

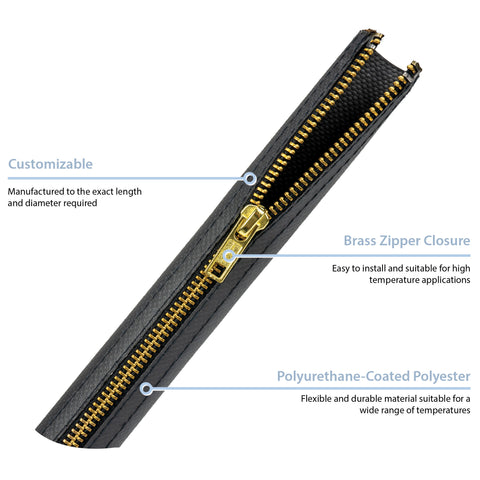

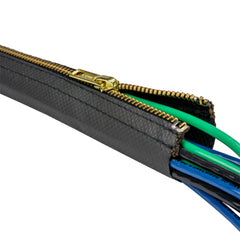

Zip-Wrap® (RPH) is a medium weight, flexible, and rugged, complete 360° protection solution for wires, cables, hoses, and other components. Zip-Wrap® (RPH) can be customized to fit virtually any length and size, allowing for easy installation with a zipper closure system.

Zip-Wrap® (RPH) is comprised of a polyurethane-coated polyester outer jacketing material (RPH-14), combined with a heat resistant brass zipper closure. The RPH-14 material is a medium weight, highly flexible, durable polyurethane coated polyester fabric, which is resistant to wear, and high and extremely low temperatures. These materials are combined and sewn with high-temperature aramid Kevlar thread, resistant to bacteria and mildew. Together, these components provide strength and abrasion protection reinforcement for wires or cables and allow for a seamless installation and re-entry without the need for additional tooling. This product also has excellent versatility in both temperature ranges of -67°F to 356°F.

- A flexible polyurethane-coated polyester material, and our high-temp brass zipper closure sewn using our strong, heat resistant Kevlar thread

- Excellent abrasion protection

- Can withstand high and extreme low temperatures

- Wear resistant

- No additional tools required; easy installation and re-entry

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Shelf-Life:

- Zipper Color:

RPH-14

- Base Fabric:

- REACH:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tear Strength:

Toothed Zipper (High-Temp Brass)

Kevlar Thread

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Zip-Wrap® (RPH) High Temperature Cable Bundling

A flexible yet rugged solution that is equipped with a secure, heat-resistant brass zipper and durable sleeve to handle extremely high and low temperatures.

Drawing Number(s): ZT18-07-005

Selected Part Number: ZT18-07-005-0.5-B-BR

Features

Benefits

Zip-Wrap® (RPH) High Temperature Cable Bundling

Zip-Wrap® (RPH) High Temperature Cable Bundling

MATERIAL SPECIFICATIONS