Overview

- 360-degree pull-through jacket with a nylon cloth leader

- Abrasion and chemical-resistant sleeving

- Cut-to-length cable sleeving available in multiple color options

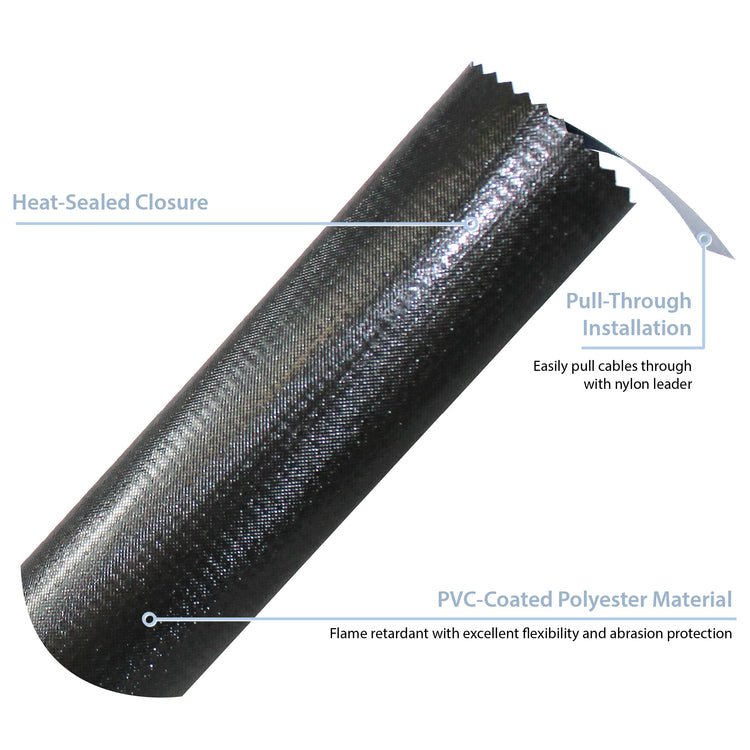

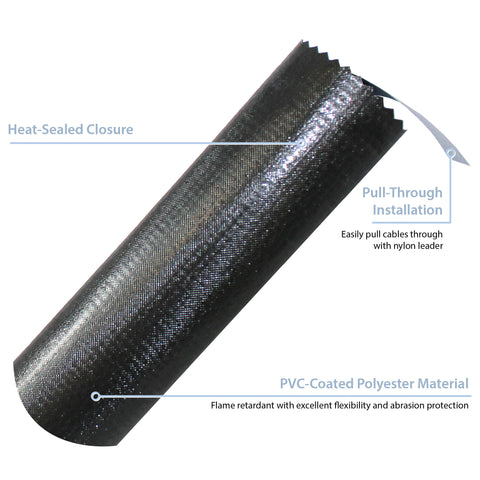

ZTT® (PVL) is an advanced cable management solution featuring PVL-10 sleeving and a nylon cloth leader. The PVL-10 sleeving is made of an abrasion-resistant, fire-retardant, PVC-coated polyester that is both lightweight and flexible. Designed for industrial and high-performance applications, the wiring sleeve comes in multiple color options for easy color-coding and identification. The integrated nylon cloth leader simplifies the installation process, making it easy to route and protect cables or wires even on long assemblies.

No special tools are required—just a pair of scissors to cut the sleeving to the desired length. ZTT® (PVL) is manufactured using heat-sealed edges to create a tear-resistant solution, ensuring total protection against environmental factors such as fluids and debris. This innovative cable sleeve provides outstanding protection and an improved appearance over traditional cable management techniques such as tape wrapping and nylon cable ties. Whether your application demands a 360-degree cable management solution or easy tool-free installation, ZTT® (PVL) offers an ideal solution.

ZTT® (PVL) sleeving is designed to accommodate round or flat components, available in diameters from 0.75" to 3.25", with an operational temperature range from -40°F to 179°F (-40°C to 82°C).

- Flexible, abrasion-resistant PVC-coated polyester sleeving

- Nylon cloth leader for quick and easy installation

- Available in multiple colors for streamlined color-coding

- Can be cut to any length as needed

- Tool-free installation for convenience

Specifications

Overall Performance

- Material:

- Diameter:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

PVL-10

- Mil-Spec:

- REACH:

- Chemical Resistance:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Similar products

|

|

|

|

| NAME | Z FLEX® (PFR) POLYURETHANE PULL-THROUGH CABLE SLEEVE | CHANNEL-WRAP® (PFR) ROBOTIC CABLE SLEEVING | Z FLEX® (63) PVC PULL-THROUGH CABLE SLEEVE |

| DESCRIPTION | A military-grade, flame-retardant, pull-through cable and wire protection solution that has a nylon cloth leader. | A flexible, wrap-around robotic cable management sleeve with a Velcro-style hook-and-loop closure for bundling and protecting crucial wires and cables. | A pull-through bundling sleeve equipped with a nylon cloth leader, made of a 0.02” thick military-grade material that offers protection from abrasion & fluid. |

| Closure | Hook-and-Loop (Nylon) | ||

| RoHS | RoHS-6 | RoHS-10 | RoHS-6 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Pull Through | Wrap-Around | Pull Through |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Extreme | Extreme | Low |

| Minimum Operating Temperature | -67°F | -67°F | -4°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 224°F | 199°F | 221°F |

| Flexibility | Best | Best | Better |

| View | View | View |

ZTT® (PVL) Pull-Through Wiring Sleeve

A pull-through cable sleeving solution with a fire-retardant jacket that is available in multiple colors—equipped with a nylon cloth leader for easy installation.

Drawing Number(s): ZT93-10-002, ZT93-10-003

Selected Part Number: ZT93-10-002-1.0-B

Features

Benefits

ZTT® (PVL) Pull-Through Wiring Sleeve

ZTT® (PVL) Pull-Through Wiring Sleeve

MATERIAL SPECIFICATIONS