Overview

- Fire-retardant, reinforced polyurethane coated fabric

- Pre-installed, nylon cloth leader allows for easy pull-through of wires

- Can be cut to any desired length

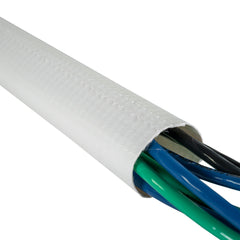

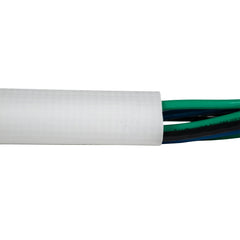

ZTT® (RPU) is a medium-weight, easy-to-clean cable management solution featuring RPU jacketing and a nylon cloth leader. The all white jacketing is made from a polyurethane coated fabric providing flexibility, fluid resistance, abrasion resistance and best fire resistance. The pre-installed, nylon cloth leader is a woven fabric made from a DuPont® type 6, mid-dull nylon yarn; and facilitates an easier pull-through method for wire or cable installation.

No additional tools are required for installation, and a standard pair of scissors can cut through the jacketing. ZTT® (RPU) is manufactured by heat-sealing one edge of the jacketing to create a teardrop style solution. This allows for complete security and protection of components inside from fluid and debris exposure. If your application demands 360-degree pull-through cable bundling that can be installed without tools, ZTT® (RPU) is the perfect solution.

ZTT® (RPU) is offered for single cables or small bundles of wires. The operational temperature range is s from -40°F to 160°F (-40°C to 71°C). Standard diameters range from 0.25” to 2”, with custom sizes and shapes available upon request.

- Cut to length for varying requirements

- Available in custom sizes and lengths

- Operational temperature range of -40°F to 160°F (-40°C to 71°C)

- No additional tools are required for installation

- Jacketing is flexible, abrasion resistant and fire retardant

- Simply pre-wrap components, then use cloth leader for easy pull-through

Specifications

Overall Performance

- Diameter:

- Material:

- Flame Retardant:

- Thickness:

- Material Type:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Tensile Strength:

RPU-17

- Solvent Resistance:

- REACH:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Similar products

|

|

|

|

| NAME | Z FLEX® (PFR) POLYURETHANE PULL-THROUGH CABLE SLEEVE | CHANNEL-WRAP® (PFR) ROBOTIC CABLE SLEEVING | Z FLEX® (63) PVC PULL-THROUGH CABLE SLEEVE |

| DESCRIPTION | A military-grade, flame-retardant, pull-through cable and wire protection solution that has a nylon cloth leader. | A flexible, wrap-around robotic cable management sleeve with a Velcro-style hook-and-loop closure for bundling and protecting crucial wires and cables. | A pull-through bundling sleeve equipped with a nylon cloth leader, made of a 0.02” thick military-grade material that offers protection from abrasion & fluid. |

| Closure | Hook-and-Loop (Nylon) | ||

| RoHS | RoHS-6 | RoHS-10 | RoHS-6 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Pull Through | Wrap-Around | Pull Through |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Extreme | Extreme | Low |

| Minimum Operating Temperature | -67°F | -67°F | -4°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 224°F | 199°F | 221°F |

| Flexibility | Best | Best | Better |

| View | View | View |

ZTT® (RPU) Polyurethane Pull-Through Cable Sleeve

A medium-weight, pull-through cable sleeving solution with a fire-retardant jacket and a nylon cloth leader.

Drawing Number(s): ZT19-10-004

Selected Part Number: ZT19-10-004-0.25-W-W

Features

Benefits

ZTT® (RPU) Polyurethane Pull-Through Cable Sleeve

ZTT® (RPU) Polyurethane Pull-Through Cable Sleeve

MATERIAL SPECIFICATIONS